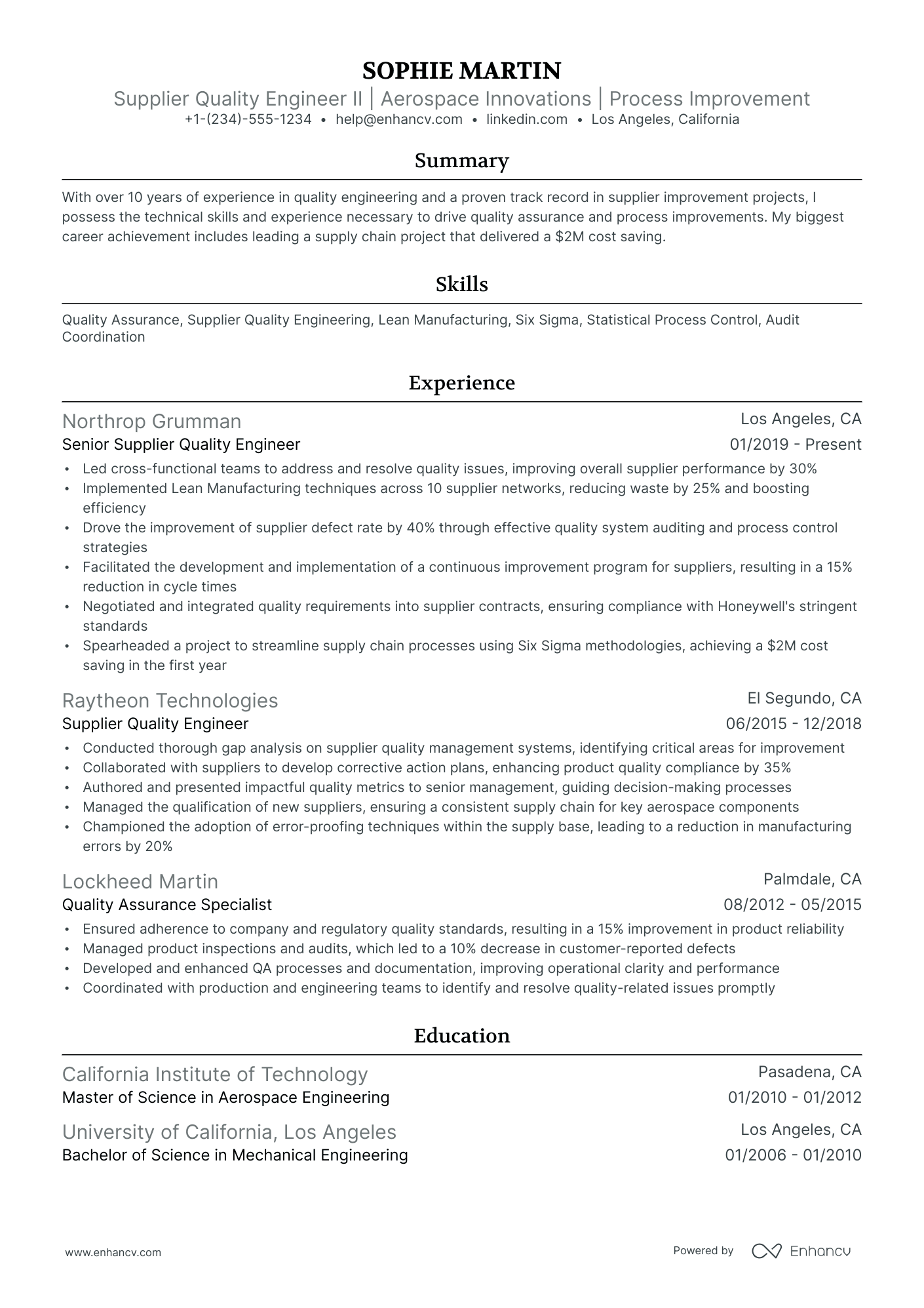

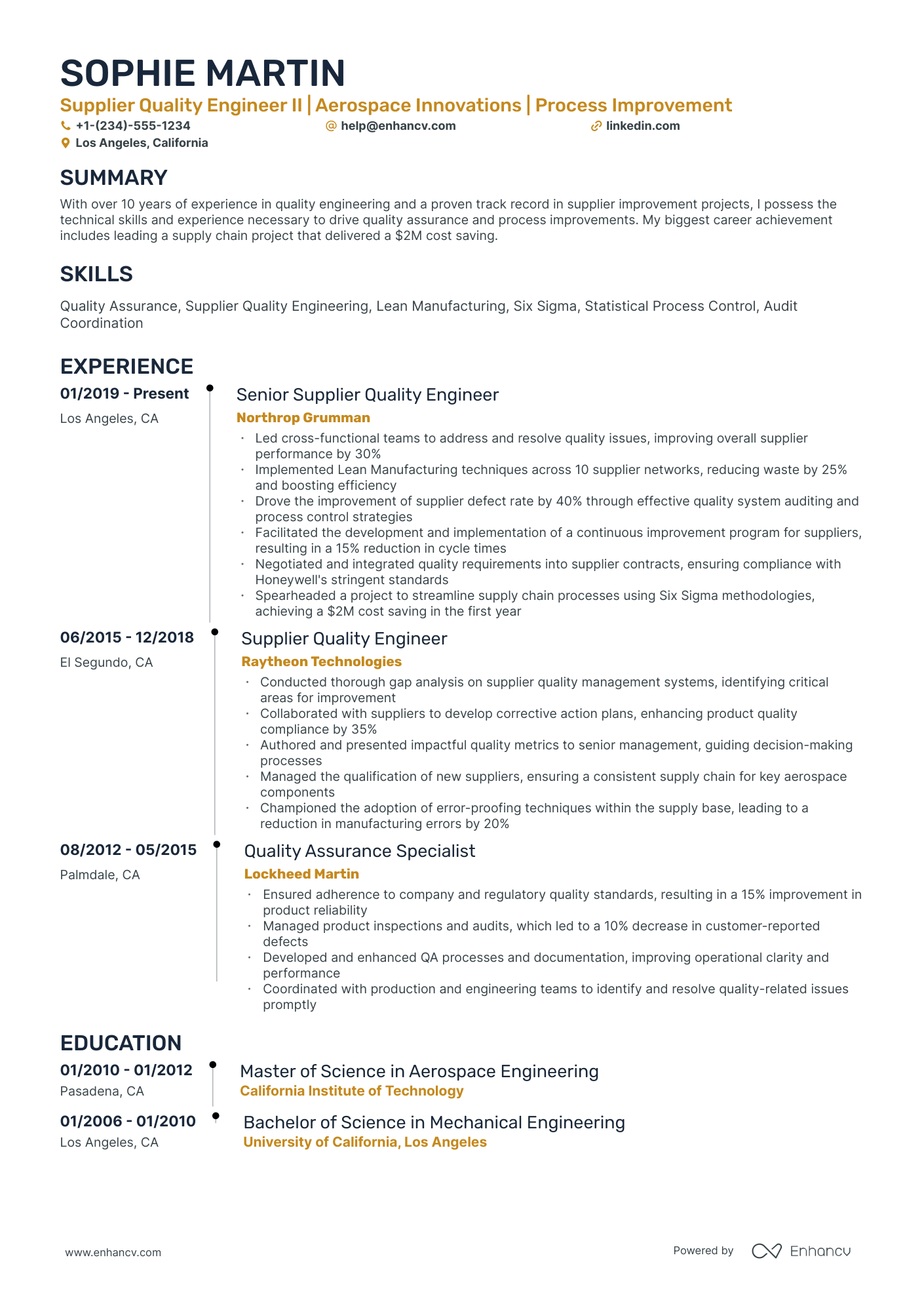

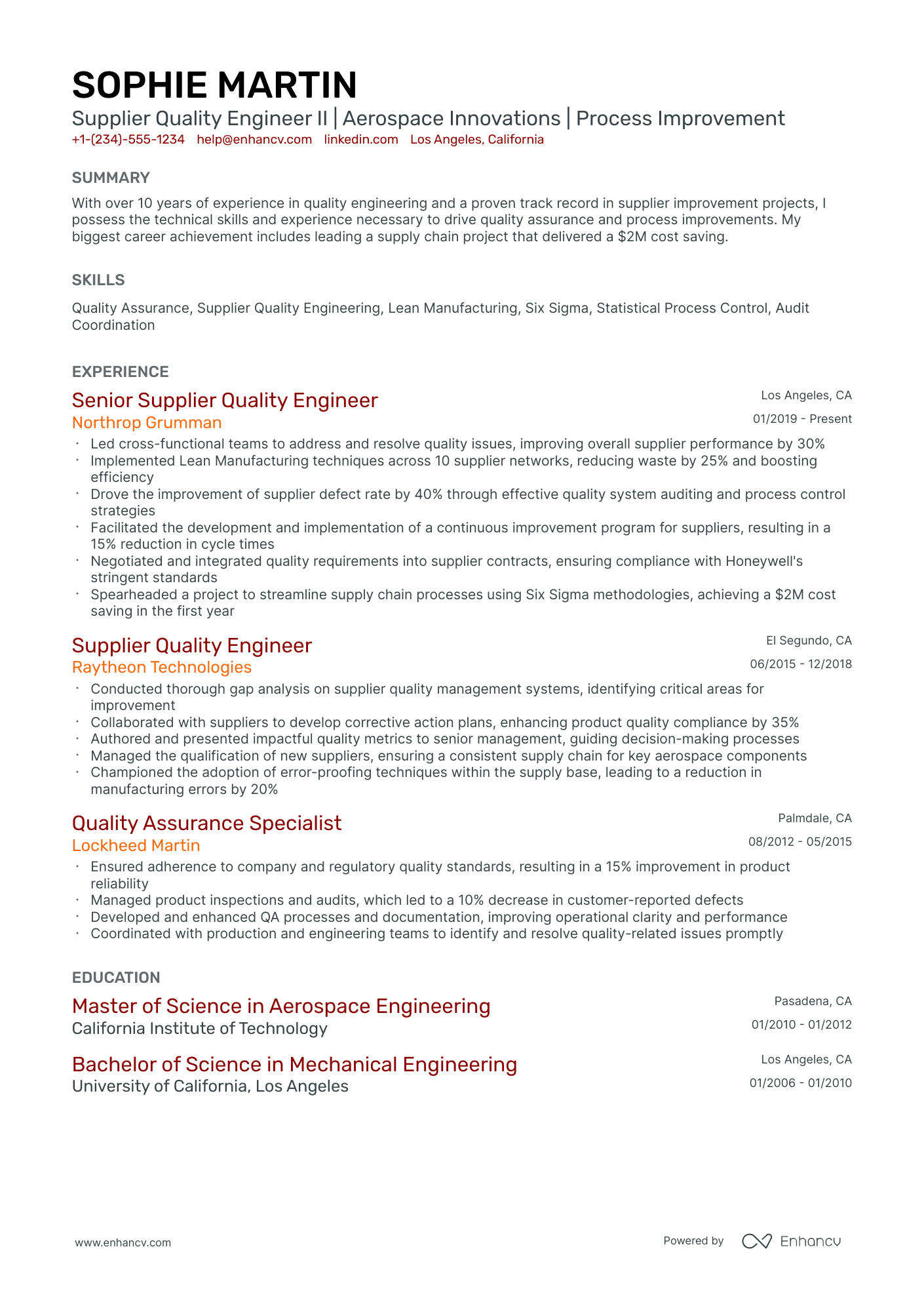

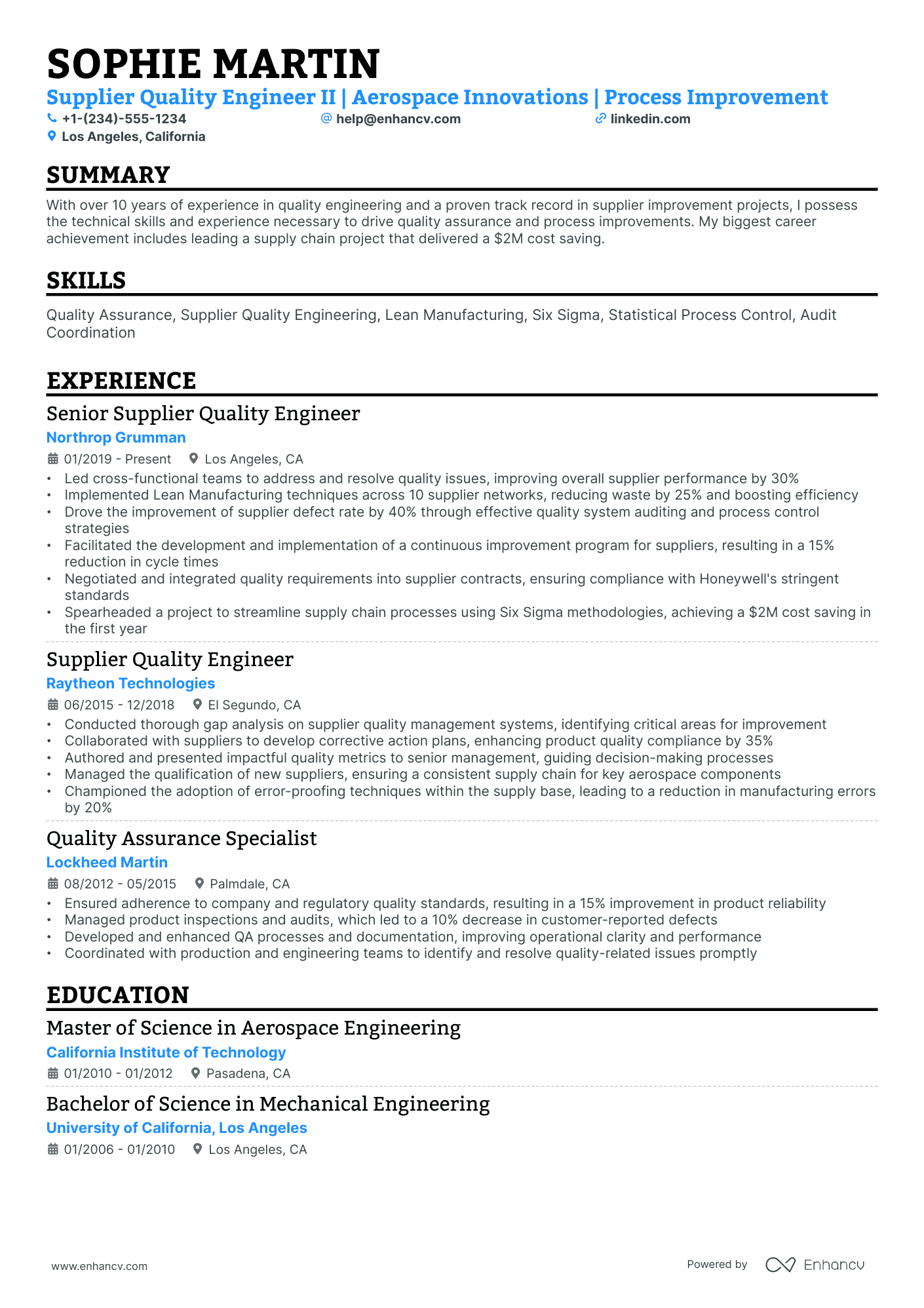

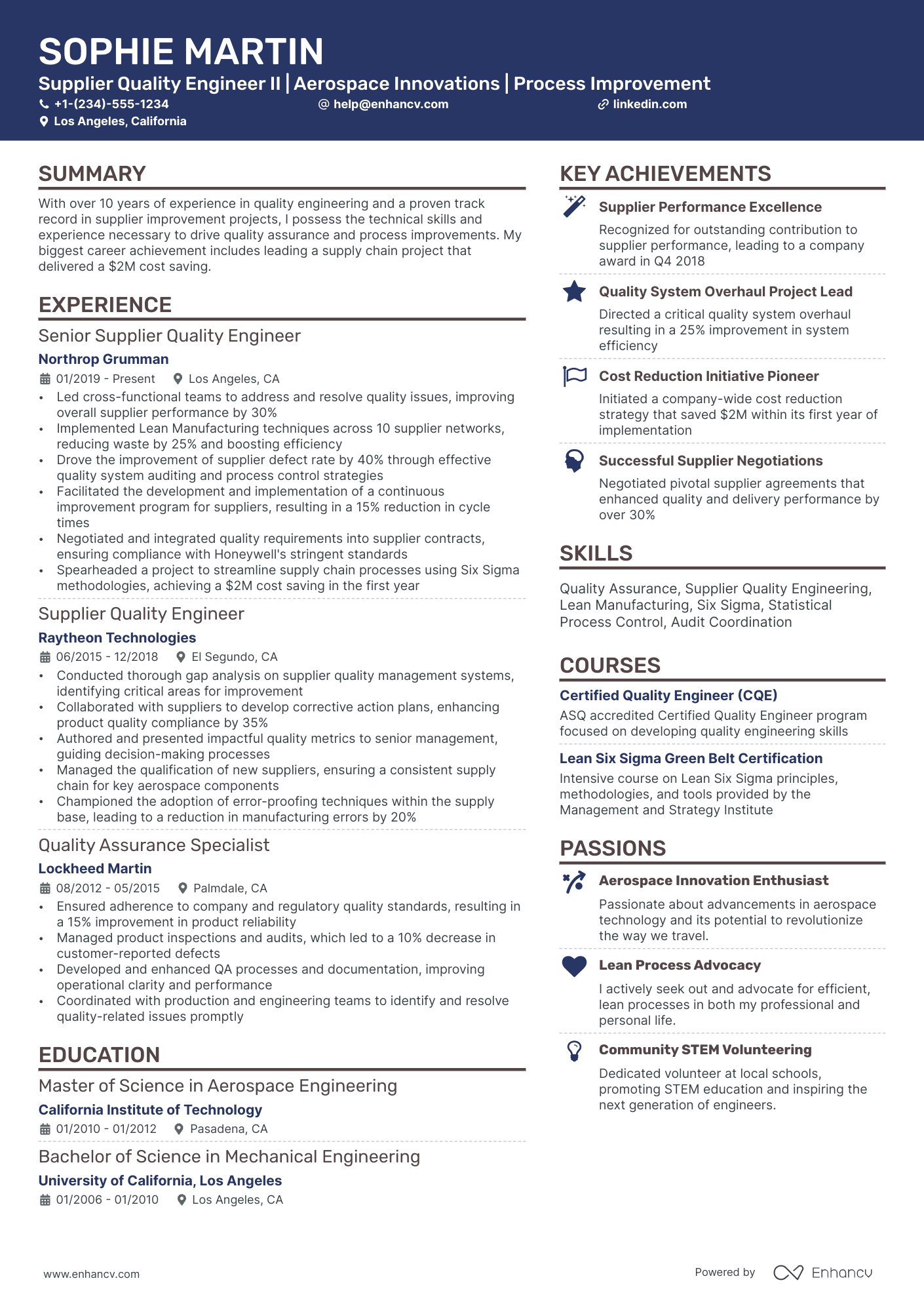

As a supplier quality engineer, articulating your complex collaboration and problem-solving experiences on a resume can be challenging. Our guide offers targeted advice and examples on how to distill these intricate interactions into impactful bullet points that will catch an employer's eye.

- Get inspired from our supplier quality engineer resume samples with industry-leading skills, certifications, and more.

- Show how you can impact the organization with your resume summary and experience.

- Introducing your unique supplier quality engineer expertise with a focus on tangible results and achievements.

If the supplier quality engineer resume isn't the right one for you, take a look at other related guides we have:

- QA Manager Resume Example

- Quality Technician Resume Example

- Quality Assurance Engineer Resume Example

- Quality Control Manager Resume Example

- Quality Assurance Technician Resume Example

- Data Quality Analyst Resume Example

- Quality Control Engineer Resume Example

- Quality Supervisor Resume Example

- Quality Control Technician Resume Example

- Quality Control Inspector Resume Example

Creating the Best Supplier Quality Engineer Resume Format: Four Simple Steps

The most appropriate supplier quality engineer resume format is defined by precision and a systematic approach. What is more, it should reflect upon how your application will be assessed by recruiters. That is why we've gathered four of the most vital elements to keep in mind when designing your resume:

- It's all about presenting how your experience or skills align with the job. Use the reverse-chronological resume format , if your expertise is relevant to the supplier quality engineer role. Otherwise, select the functional skill-based resume format or the hybrid resume format to shift the focus to your skill set.

- Resume header - make sure you've filled out all relevant (and correct) information, like your contact details and link to your portfolio.

- Resume length - unless you've over a decade of applicable expertise in the field, stick with a one-page resume format. If you'd like to present more of your professional experience, go up to two pages.

- Resume file - submit your supplier quality engineer resume in a PDF format to ensure all information stays in the same place.

Think about the market’s preferences – a Canadian resume, for instance, could have a different layout.

Upload & Check Your Resume

Drop your resume here or choose a file. PDF & DOCX only. Max 2MB file size.

PRO TIP

The more time and effort you've put into obtaining the relevant certificate, the closer to the top it should be listed. This is especially important for more senior roles and if the company you're applying for is more forward-facing.

Essential sections that should make up your supplier quality engineer resume include:

- The header - with your contact details (e.g. email and telephone number), link to your portfolio, and headline

- The summary (or objective) - to spotlight the peaks of your professional career, so far

- The experience section - with up to six bullets per role to detail specific outcomes

- The skills list - to provide a healthy mix between your personal and professional talents

- The education and certification - showing your most relevant degrees and certificates to the supplier quality engineer role

What recruiters want to see on your resume:

- Experience in supplier evaluation, auditing, and qualification processes.

- Knowledge of quality management systems (e.g., ISO 9001) and industry-specific standards.

- Proficiency in root cause analysis and corrective action implementation.

- Familiarity with statistical process control (SPC), Six Sigma, or other quality improvement methodologies.

- Demonstrated history of managing cross-functional teams and projects to improve supplier quality performance.

Experts' Advice on Writing Your Supplier Quality Engineer Resume Experience

While the excitement and motivation for writing your supplier quality engineer resume was present in the first hour (or so), you now find yourself staring at the blank page.

The resume experience section is the one that allows you to make a memorable impression by matching job requirement with your past jobs and accomplishments.

To help you write this resume section, here are four mistakes you need to avoid:

- Listing every job you have had so far, including the irrelevant ones. Before that, consider each of your past roles based on relevancy to the role. It may be the case that the job you had 15 years ago may have taught you invaluable skills that are appropriate for the role;

- Including irrelevant work experience items. Those are past jobs that aren't linked with the role you're applying for (or so they seem). Consider how your past jobs will serve your professional presentation: will they be filling in a gap in your work history, or just taking up space?

- Focusing on responsibilities instead of accomplishments. Your supplier quality engineer resume shouldn't just be telling recruiters what you did in the past - as it's most often the case that candidates have had similar responsibilities. But, rather, the experience section should showcase the success you've attained in each past role, thanks to your unique skill set;

- Consider listing just your professional experience. Any role you've had in the past - e.g. volunteering, internships, etc. - can make it into your supplier quality engineer resume experience section. Make sure to include it alongside numbers and results.

Two more things you need to remember about your resume experience section.

The first are keywords. Or those specific job requirements that are crucial for the role . Ensure you've integrated them across your experience section to get sorted closer to the ideal candidate profile by the Applicant Tracker System (ATS).

The second are action verbs. Each of your experience bullets should start with a strong action verb, followed by your specific skill and your on the job achievements. Follow this formula to hint to recruiters what your unique value as a professional is.

Still with us? In the next section, we will show you how industry-leading professionals have avoided the four most common mistakes, while integrating keywords and action verbs in their experience section.

- Developed a supplier qualification program resulting in a 25% reduction in part defects and a 15% improvement in overall product quality.

- Managed cross-functional teams to perform on-site supplier audits, assessing compliance with ISO 9001 standards and implementing corrective actions.

- Led a project to transition suppliers to more sustainable materials, achieving a 20% reduction in the environmental impact of products.

- Designed and executed a statistical process control system for critical supplier components, reducing variability and improving consistency by 30%.

- Coordinated with global suppliers to enhance manufacturing processes, elevating our suppliers' capabilities and resulting in a 12% increase in efficiency.

- Implemented quality performance metrics for key suppliers and initiated quarterly reviews, which improved supplier performance by 18%.

- Collaborated with R&D and suppliers on new product launches, ensuring 100% of materials met stringent quality benchmarks before release.

- Conducted process validation assessments for 50+ suppliers, improving process reliability and product life cycle.

- Orchestrated the root cause analysis for product failures, which led to a 40% reduction in warranty claims.

- Oversaw the development and implementation of supplier improvement programs that resulted in a 10% cost reduction while maintaining quality standards.

- Negotiated quality agreements with new suppliers, contributing to an 8% faster time-to-market for new products.

- Pioneered the deployment of quality-focused training for supplier personnel, which decreased defects rate by 22%.

- Executed a comprehensive supplier risk management strategy that minimized disruptions by identifying potential risks early.

- Collaborated closely with procurement to drive supplier integration and lean initiatives, which yielded an annual savings of $3 million.

- Championed a ‘Zero Defect’ program across key suppliers, which cut down the defect ratio by 50% in critical components.

- Developed a supplier scorecard and evaluation system that increased the accountability and performance of suppliers by 15% year-over-year.

- Enhanced supplier selection criteria using comprehensive data analysis, improving on-time delivery by 20% and reducing material shortages.

- Managed the transition of a critical product line to a new supplier, which cut direct costs by 13% while upholding quality standards.

- Facilitated the supplier transition for a high-volume product, preserving product quality and reducing costs by $4.5M annually.

- Cultivated strategic partnerships with suppliers to share best practices, improving the Mean Time Between Failures (MTBF) by 500 hours.

- Drove a continuous quality improvement plan that resulted in a 35% enhancement in part reliability from top-tier suppliers.

- Initiated a supplier development program which optimized supplier deliverables and cut procurement costs by 10%.

- Collaborated on a cross-functional team to map out a supplier consolidation strategy, improving sourcing efficiency by 25%.

- Led the qualification of new suppliers in Asia, expanding the company's supplier base and reducing lead times by 15% for critical components.

The following content includes information from "O*NET OnLine" by the U.S. Department of Labor, Employment and Training Administration (USDOL/ETA). Used under the CC BY 4.0 license. The data represents the top responsibilities present on the task lists for supplier quality engineer professionals.

Top Responsibilities for Supplier Quality Engineer:

- Analyze information to determine, recommend, and plan installation of a new system or modification of an existing system.

- Analyze user needs and software requirements to determine feasibility of design within time and cost constraints.

- Confer with data processing or project managers to obtain information on limitations or capabilities for data processing projects.

- Confer with systems analysts, engineers, programmers and others to design systems and to obtain information on project limitations and capabilities, performance requirements and interfaces.

- Consult with customers or other departments on project status, proposals, or technical issues, such as software system design or maintenance.

- Coordinate installation of software system.

- Design, develop and modify software systems, using scientific analysis and mathematical models to predict and measure outcomes and consequences of design.

- Determine system performance standards.

- Develop or direct software system testing or validation procedures, programming, or documentation.

- Modify existing software to correct errors, adapt it to new hardware, or upgrade interfaces and improve performance.

Quantifying impact on your resume

- Detail the percentage reduction in supplier defect rates year-over-year under your quality management.

- Highlight the number of supplier audits conducted and the subsequent compliance rate improvements.

- Specify the dollar value of cost savings realized through process improvements or negotiation with suppliers.

- Quantify the reduction in product return rates due to enhanced supplier quality controls.

- Include the number of suppliers you have qualified or re-qualified for business to underscore your due diligence.

- State the percentage increase in on-time delivery from suppliers after implementing process enhancements.

- Mention the size of the supplier base you manage to illustrate the scale of your responsibilities.

- List any awards or recognition received for outstanding performance in supplier quality management.

Action verbs for your supplier quality engineer resume

Making the most of your little to none professional experience

If you're hesitant to apply for your dream job due to limited professional experience, remember that recruiters also value the unique contributions you can offer.

Next time you doubt applying, consider this step-by-step approach for your resume's experience section:

- Rather than the standard reverse chronological order, opt for a functional-based format. This shifts the focus from your work history to your achievements and strengths;

- Include relevant internships, volunteer work, or other non-standard experiences in your supplier quality engineer resume's experience section;

- Utilize your education, qualifications, and certifications to bridge gaps in your supplier quality engineer resume experience;

- Emphasize your interpersonal skills and transferable skills from various industries. Often, recruiters seek a personality match, giving you an advantage over other candidates.

Recommended reads:

PRO TIP

If you happen to have some basic certificates, don't invest too much of your supplier quality engineer resume real estate in them. Instead, list them within the skills section or as part of your relevant experience. This way you'd ensure you meet all job requirements while dedicating your certificates to only the most in-demand certification across the industry.

Featuring Your Hard Skills and Soft Skills on Your Supplier Quality Engineer Resume

The skills section of your supplier quality engineer resume needs to your various capabilities that align with the job requirements. List hard skills (or technical skills) to showcase to potential employers that you're perfectly apt at dealing with technological innovations and niche software. Meanwhile, your soft skills need to detail how you'd thrive within your new, potential environment with personal skills (e.g. resilience, negotiation, organization, etc.) Your supplier quality engineer resume skills section needs to include both types of skills to promote how you're both technical and cultural fit. Here's how to create your bespoke supplier quality engineer skills section to help you stand out:

- Focus on skill requirements that are listed toward the top of the job advert.

- Include niche skills that you've worked hard to obtain.

- Select specific soft skills that match the company (or the department) culture.

- Cover some of the basic job requirements by including important skills for the supplier quality engineer role - ones you haven't been able to list through the rest of your resume.

Get inspired with our supplier quality engineer sample skill list to list some of the most prominent hard and soft skills across the field.

Top skills for your supplier quality engineer resume:

Statistical Process Control (SPC)

Failure Mode and Effects Analysis (FMEA)

Root Cause Analysis (RCA)

Quality Management Systems (QMS)

ISO 9001 Standards

Six Sigma methodologies

Supplier Auditing Tools

Measurement System Analysis (MSA)

Control Charts

Quality Improvement Tools

Communication Skills

Problem-Solving

Attention to Detail

Team Collaboration

Analytical Thinking

Negotiation Skills

Time Management

Adaptability

Leadership Skills

Conflict Resolution

Next, you will find information on the top technologies for supplier quality engineer professonals from "O*NET OnLine" by the U.S. Department of Labor, Employment and Training Administration (USDOL/ETA). Used under the CC BY 4.0 license.

Top technologies for Supplier Quality Engineer’s resume:

- Oracle Java 2 Platform Enterprise Edition J2EE

- Oracle SQL Developer

- Blackboard software

- GraphQL

- Apache Spark

- TypeScript

PRO TIP

Mention specific courses or projects that are pertinent to the job you're applying for.

Listing Your Education and Certifications on Your Supplier Quality Engineer Resume

Don't underestimate the importance of your resume education section . As it may hint at various skills (and experience) that are relevant to the job. When writing your education section:

- Include only higher education degrees with information about the institution and start/end dates

- If you're in the process of obtaining your degree, include your expected graduation date

- Consider leaving off degrees that aren't relevant to the job or industry

- Write a description of your education if it presents you with an opportunity to further showcase your achievements in a more research-focused environment

When describing your certifications on your resume, always consider their relevancy to the role. Use the same format to describe them as you would for your education. If you're wondering what the best certificates out there are for supplier quality engineer roles, check out the list below.

The top 5 certifications for your supplier quality engineer resume:

- Certified Quality Engineer (CQE) - American Society for Quality (ASQ)

- Certified Supplier Quality Professional (CSQP) - American Society for Quality (ASQ)

- Six Sigma Green Belt Certification (SSGB) - Various Institutions

- ISO 9001:2015 Lead Auditor Certification - International Register of Certificated Auditors (IRCA)

- Certified Professional in Supply Management (CPSM) - Institute for Supply Management (ISM)

The content below includes information from "O*NET OnLine" by the U.S. Department of Labor, Employment and Training Administration (USDOL/ETA). Used under the CC BY 4.0 license. The data represents the top associations for supplier quality engineer professionals.

Top US associations for a Supplier Quality Engineer professional

- Association for Computing Machinery

- Association for Information Science and Technology

- Association for Information Systems

- Association for the Advancement of Artificial Intelligence

- Association for Women in Computing

PRO TIP

Always remember that your supplier quality engineer certifications can be quantified across different resume sections, like your experience, summary, or objective. For example, you could include concise details within the expertise bullets of how the specific certificate has improved your on-the-job performance.

Recommended reads:

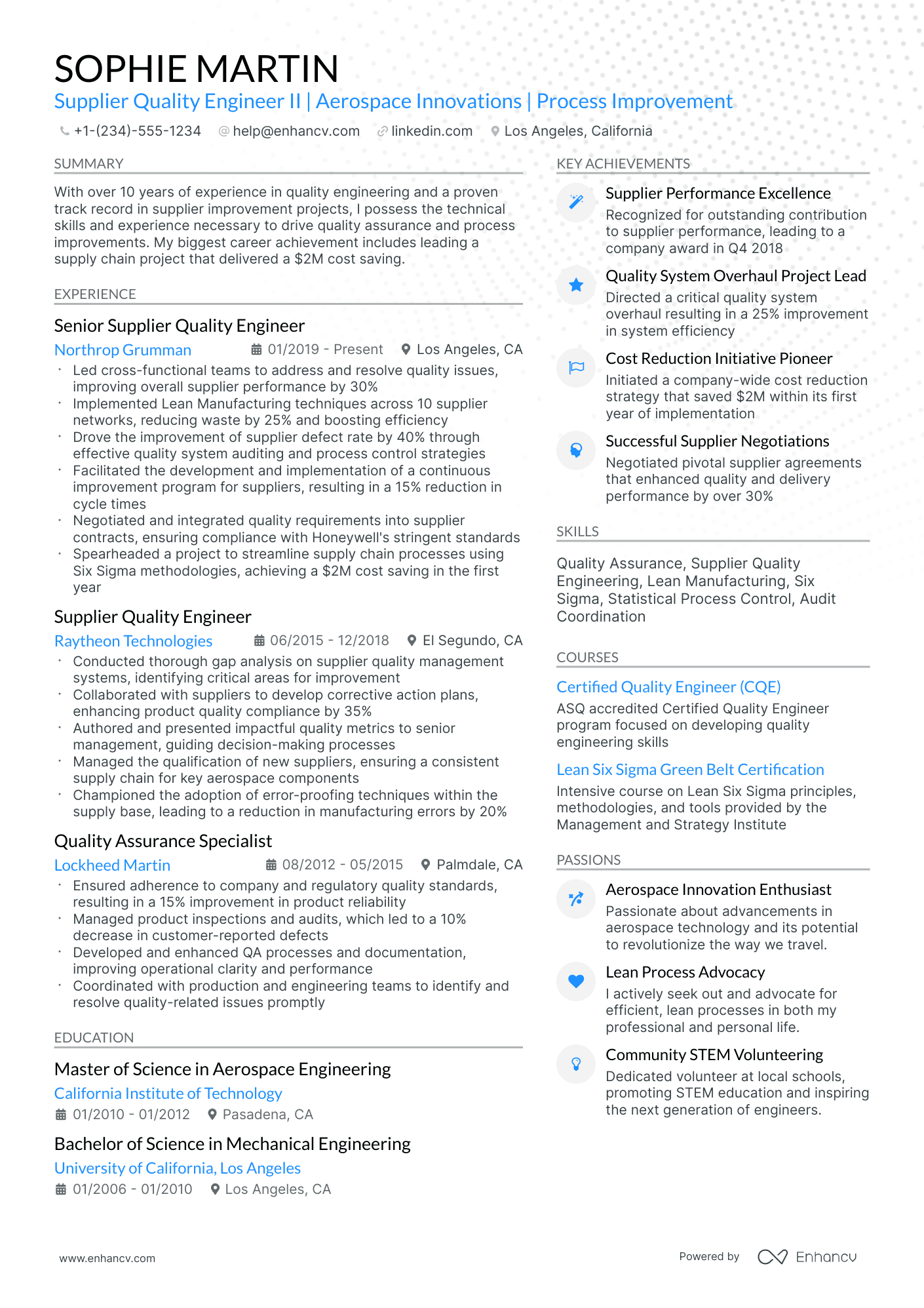

Practical Guide to Your Supplier Quality Engineer Resume Summary Or Objective

First off, should you include a summary or objective on your supplier quality engineer resume?

We definitely recommend you choose the:

- Resume summary to match job requirements with most noteworthy accomplishments.

- Resume objective as a snapshot of career dreams

Both the resume summary and objective should set expectations for recruiters as to what your career highlights are.

These introductory paragraphs (that are no more than five sentences long) should help you answer why you're the best candidate for the job.

Industry-wide best practices pinpoint that the supplier quality engineer resume summaries and objectives follow the structures of these samples:

Resume summaries for a supplier quality engineer job

- Seasoned supplier quality engineer with 8 years of experience in enhancing the manufacturing processes at a Fortune 500 automotive components producer. Expert in statistical process control, root cause analysis, and corrective action planning. Recognized for developing and implementing quality systems reducing defective rates by 30% within the first year.

- Driven professional transitioning from a successful 10-year career in aerospace engineering to supplier quality engineering, bringing a thorough understanding of material properties and failure mode effects analysis. Adept at cross-functional collaboration and eager to apply problem-solving skills to optimize supply chain integrity and performance.

- Experienced in process improvement and regulation compliance, a former Production Manager with 12 years in food and beverage industry aims to leverage systematic approach and keen eye for detail into supplier quality management, focusing on vendor evaluation and performance metrics to enhance final product excellence.

- Eager to transfer 7 years of project management experience within the renewable energy sector into supplier quality engineering, bringing a track record of successful supplier audits, and risk management initiatives, with deep knowledge of ISO 9001 and lean manufacturing principles.

- As a recent mechanical engineering graduate, eager to specialize in supplier quality engineering, I am committed to applying my academic training in quality control, process optimization, and materials science to ensure the highest standards of supply chain management and vendor satisfaction.

- Seeking to leverage my passion for technology and a strong foundation in industrial engineering education, I aim to embark on a career in supplier quality engineering, dedicated to mastering quality assurance techniques and supplier development to contribute to manufacturing excellence and product integrity.

Optimize your resume summary and objective for ATS

Drop your resume here or choose a file.

PDF & DOCX only. Max 2MB file size.

Average Salary Info by State in the US for Supplier Quality Engineer Professionals

Local salary info for Supplier Quality Engineer.” Source: My Next Move, National Center for O*NET Development. Accessed 10/15/2024

| State | Average Salary (in USD) |

|---|---|

| US National Average | $132,270 |

| California (CA) | $168,660 |

| Texas (TX) | $127,000 |

| Florida (FL) | $122,310 |

| New York (NY) | $145,470 |

| Pennsylvania (PA) | $111,910 |

| Illinois (IL) | $126,200 |

| Ohio (OH) | $107,560 |

| Georgia (GA) | $127,070 |

| North Carolina (NC) | $130,620 |

| Michigan (MI) | $103,830 |

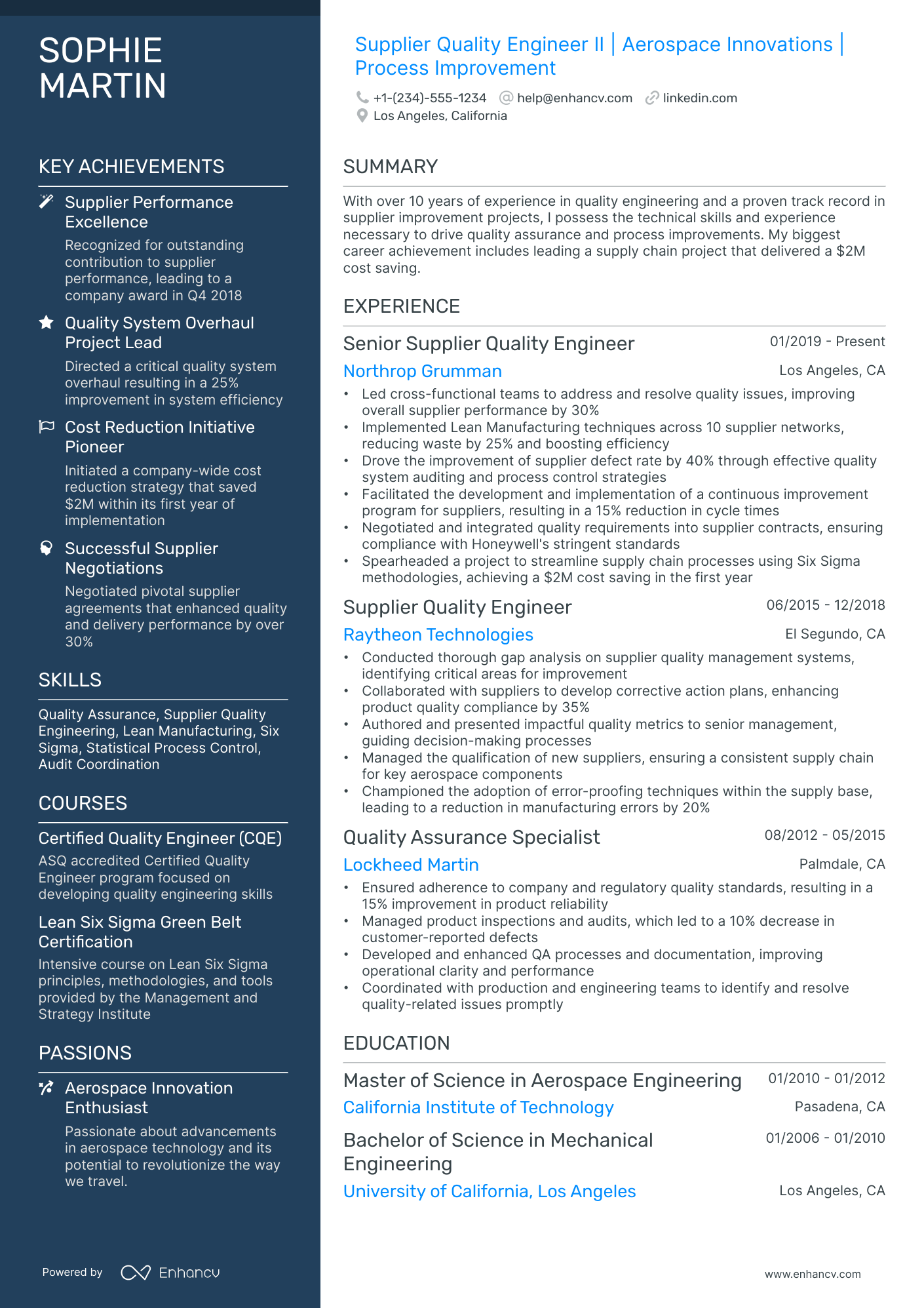

Miscellaneous Supplier Quality Engineer Resume Sections for a More Personalized Approach

Your supplier quality engineer resume can reflect even more upon your personality and best qualities - that is if you decide on including a couple of additional resume sections to support your application.

Some of the best-accepted industry-wide choices include the:

- Resume projects - getting into the outcomes of your most important work, so far;

- Languages on your resume - detailing your proficiency level;

- Special recognitions - dedicated to your most prominent industry awards;

- Hobbies and interests - defining how you spend your free time.

Key Takeaways

We trust that this Enhancv guide has been informative and useful. To summarize the essential points:

- Opt for a simple and readable format, focusing more on your supplier quality engineer achievements rather than just duties;

- Emphasize your accomplishments in the supplier quality engineer experience section over mere responsibilities;

- If lacking relevant experience, utilize various resume sections like education and volunteering to demonstrate your suitable skill set;

- Never overlook the significance of pertinent higher education, training, and certifications;

- Incorporate diverse sections in your resume to highlight not just your skills expertise but also your personality.