As a process engineer, articulating the complexity of your projects without overwhelming your potential employer can be a daunting resume challenge. Our guide provides clear strategies to concisely convey the impact of your technical expertise, ensuring that your key achievements stand out while maintaining readability.

- Defining the highlights of your process engineer career through your resume summary, objective, and experience.

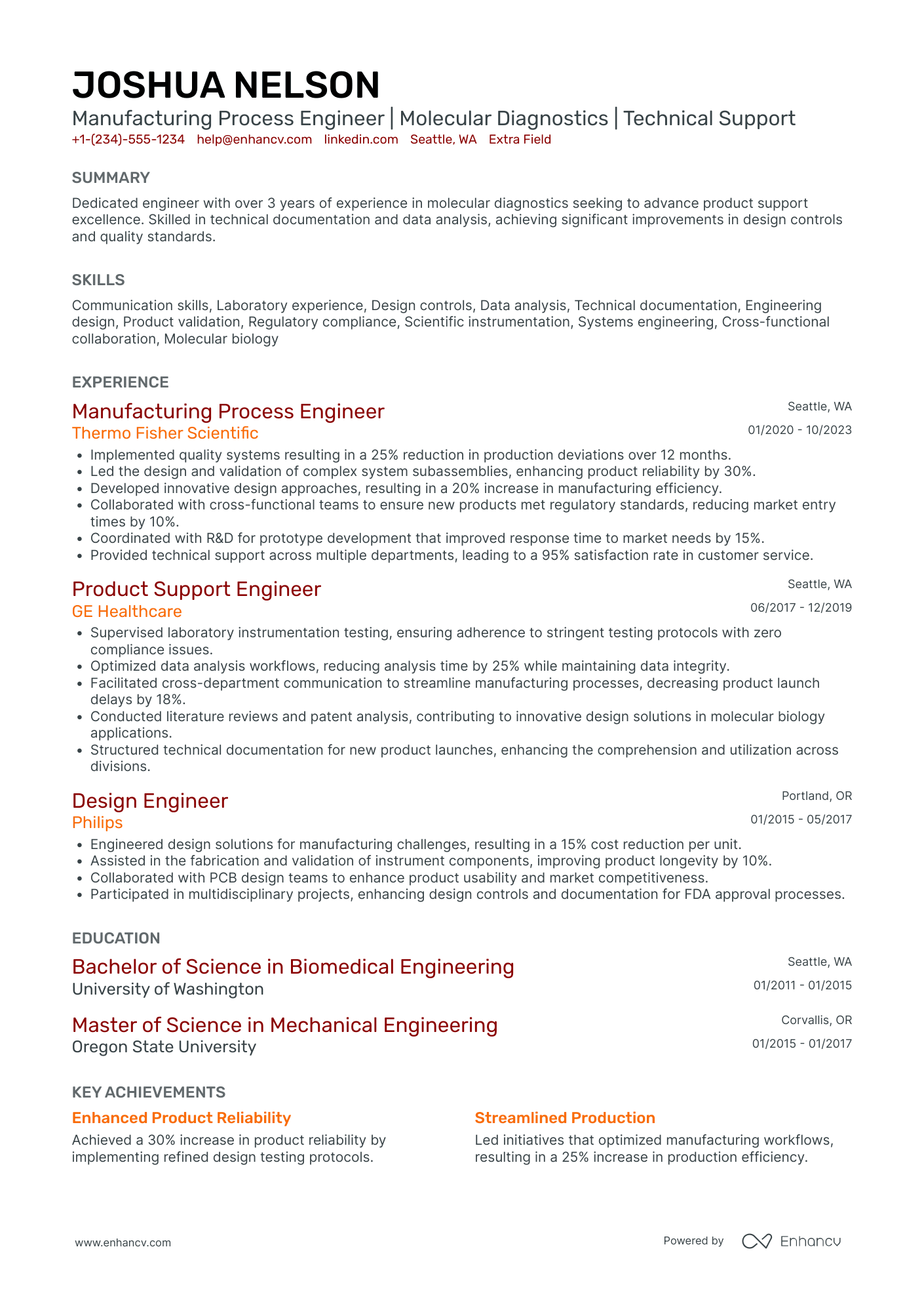

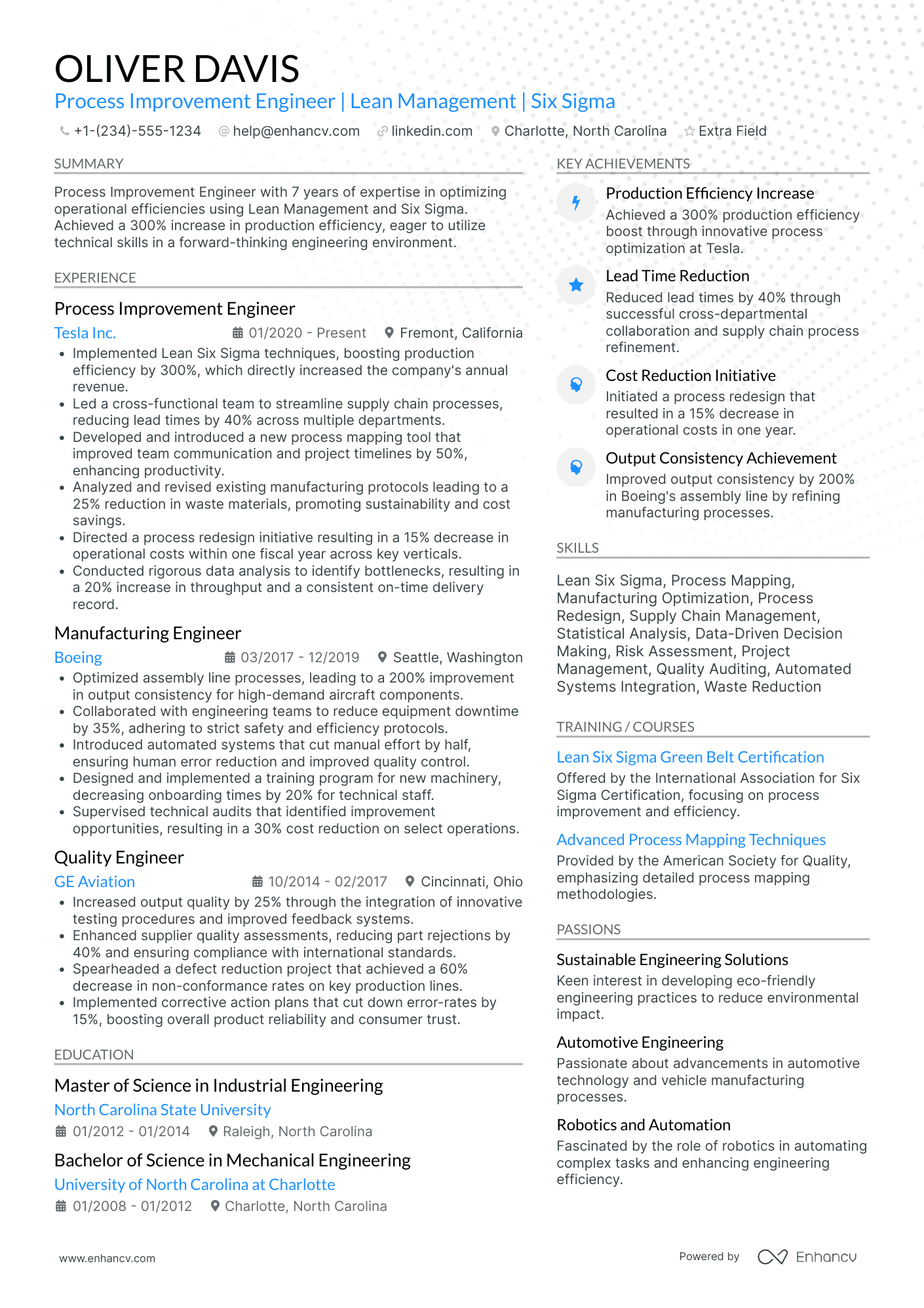

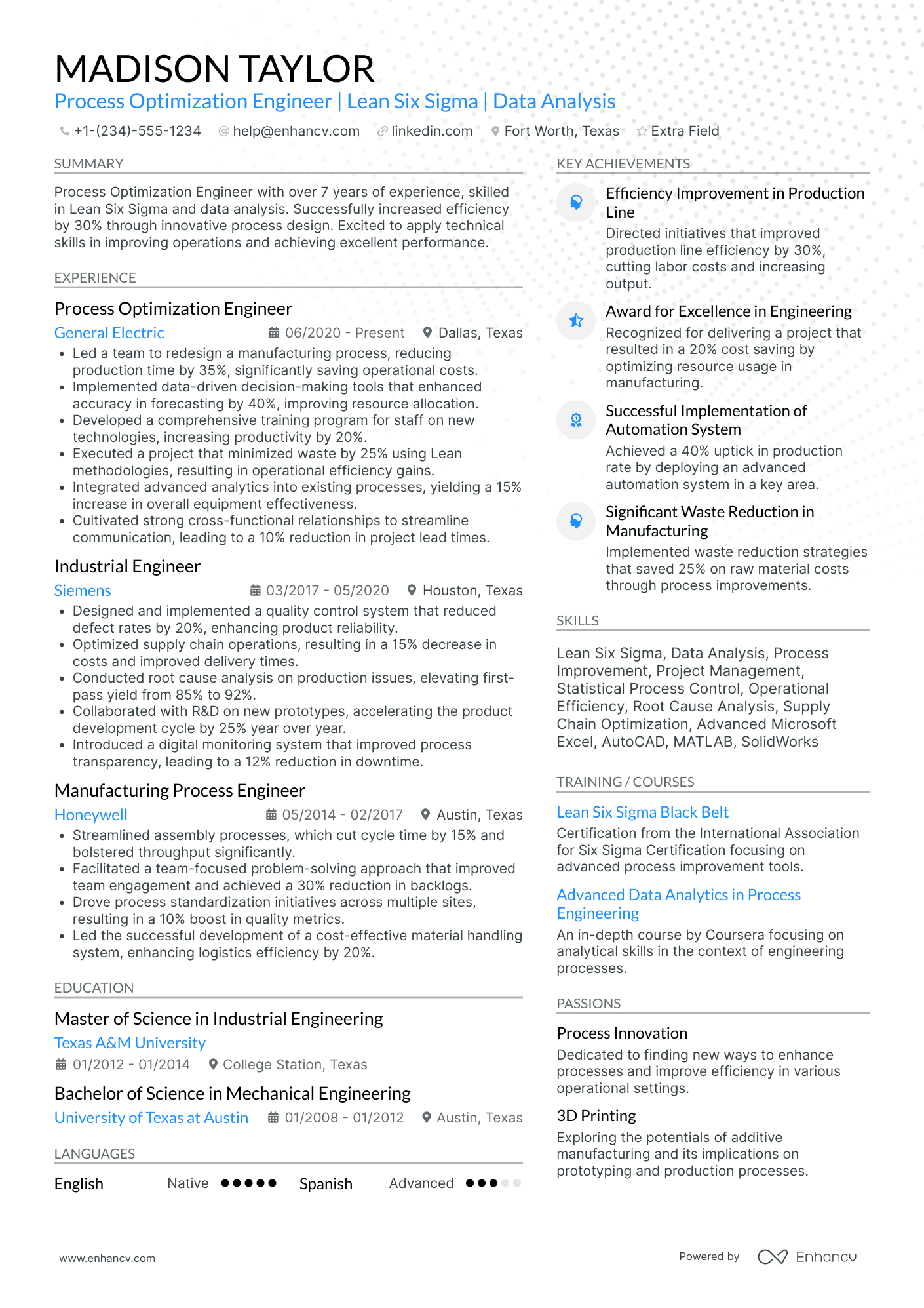

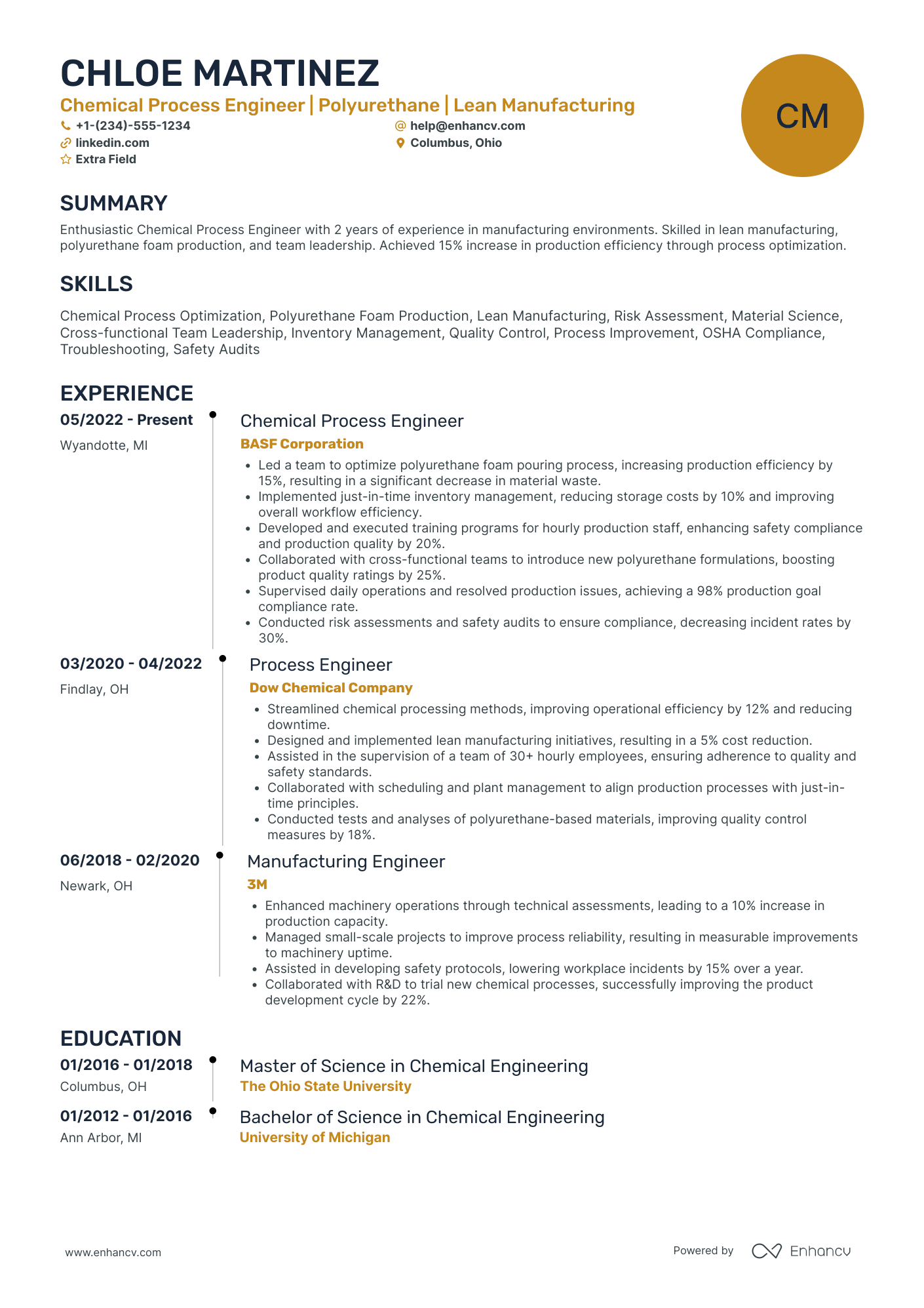

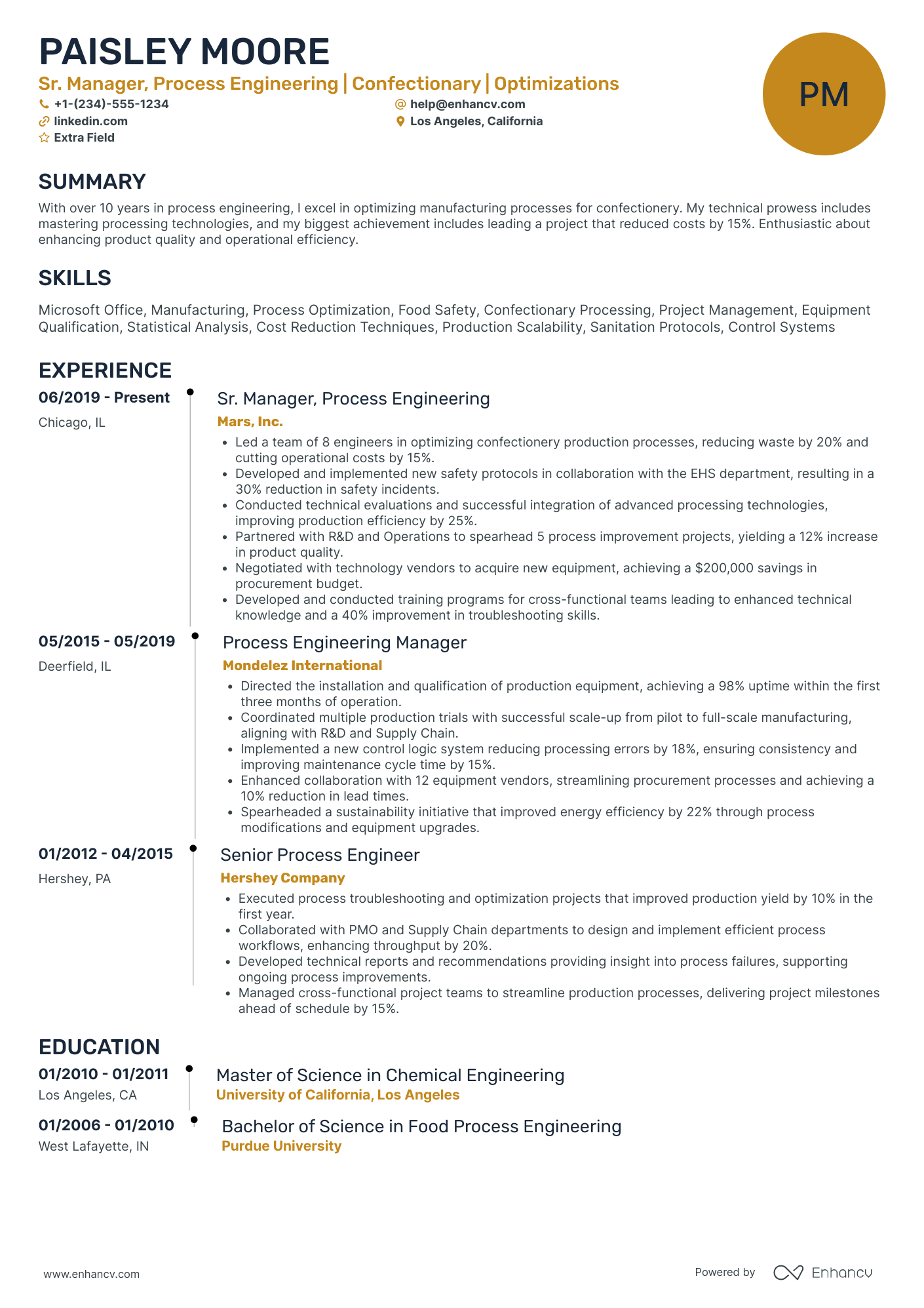

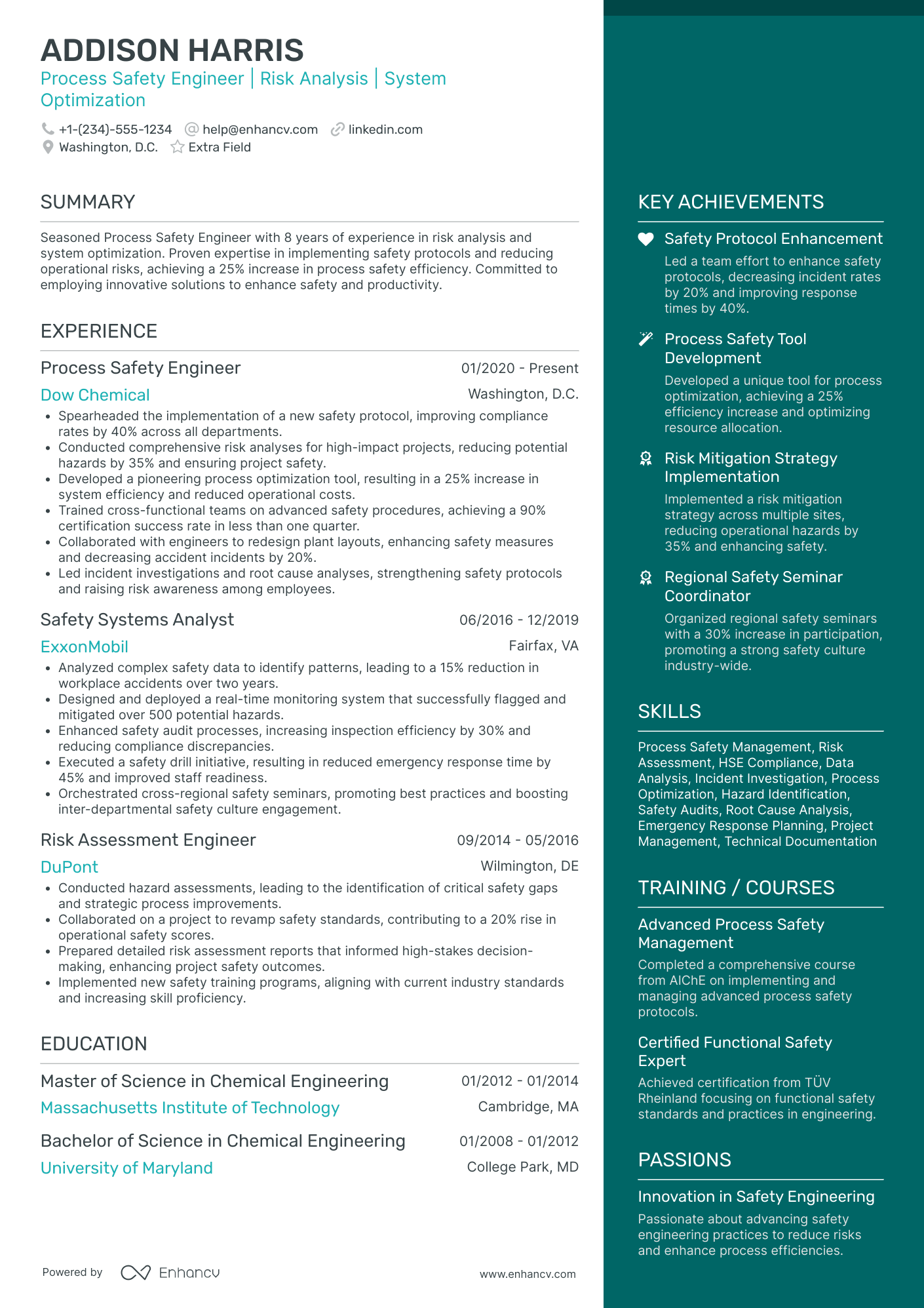

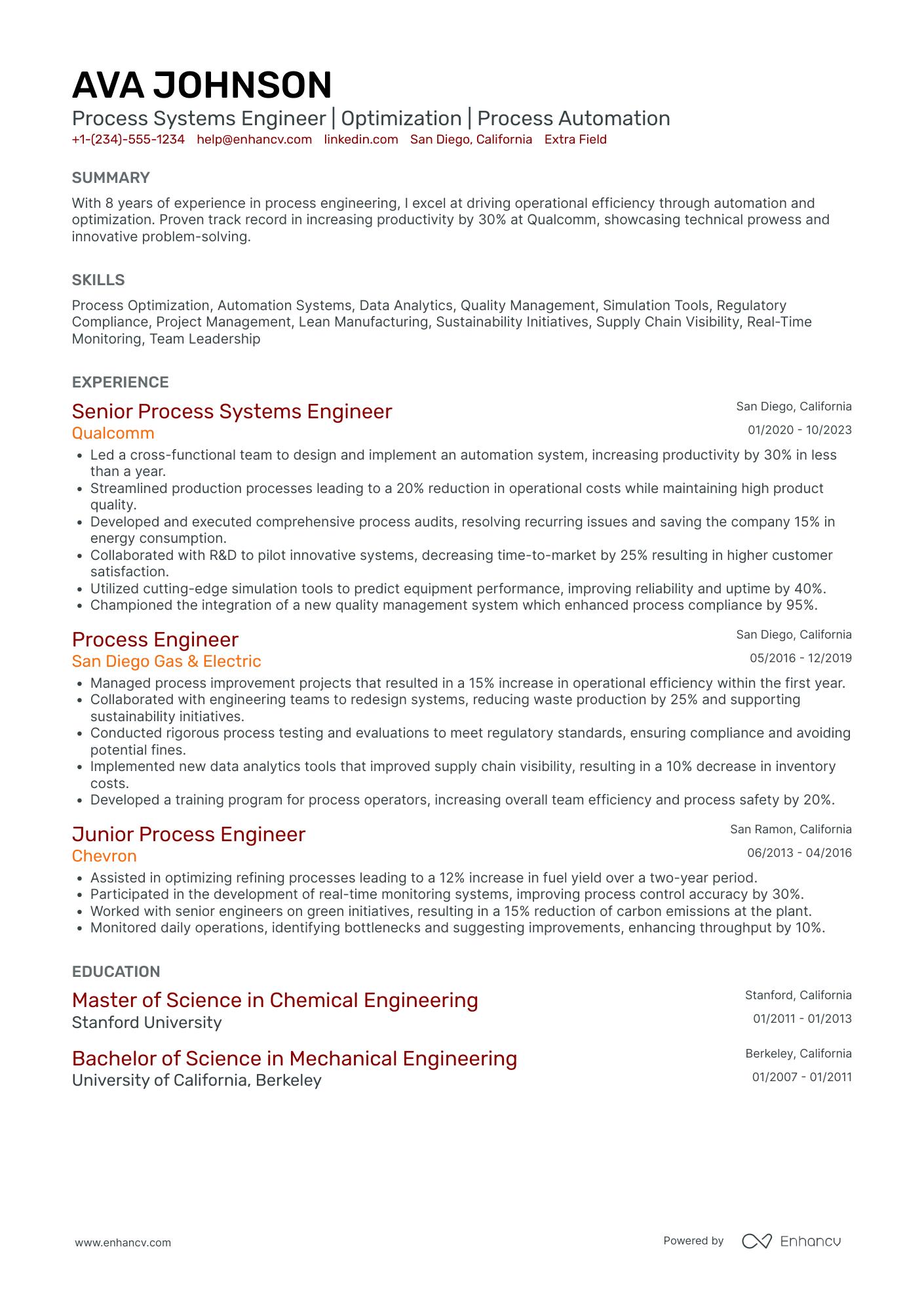

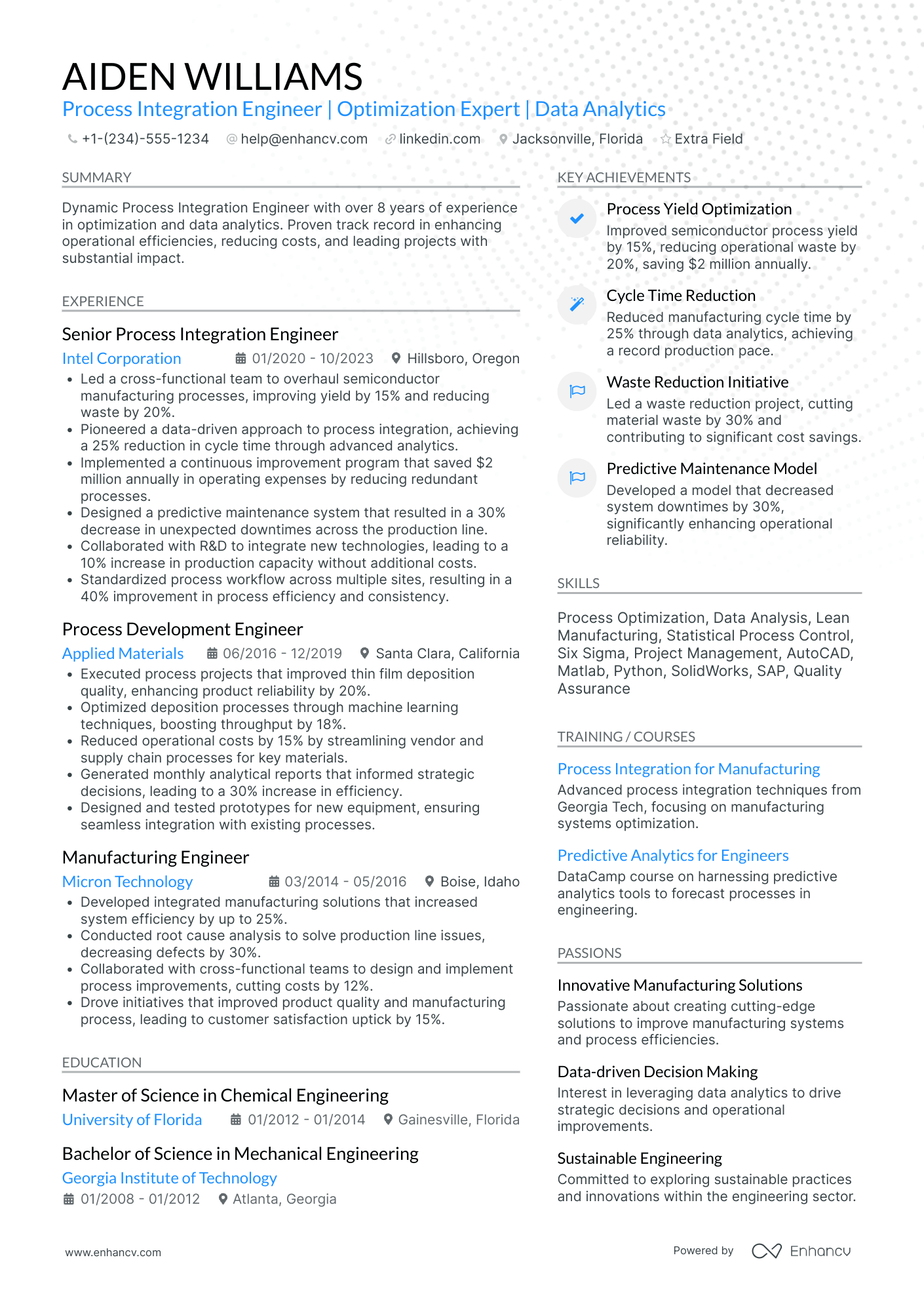

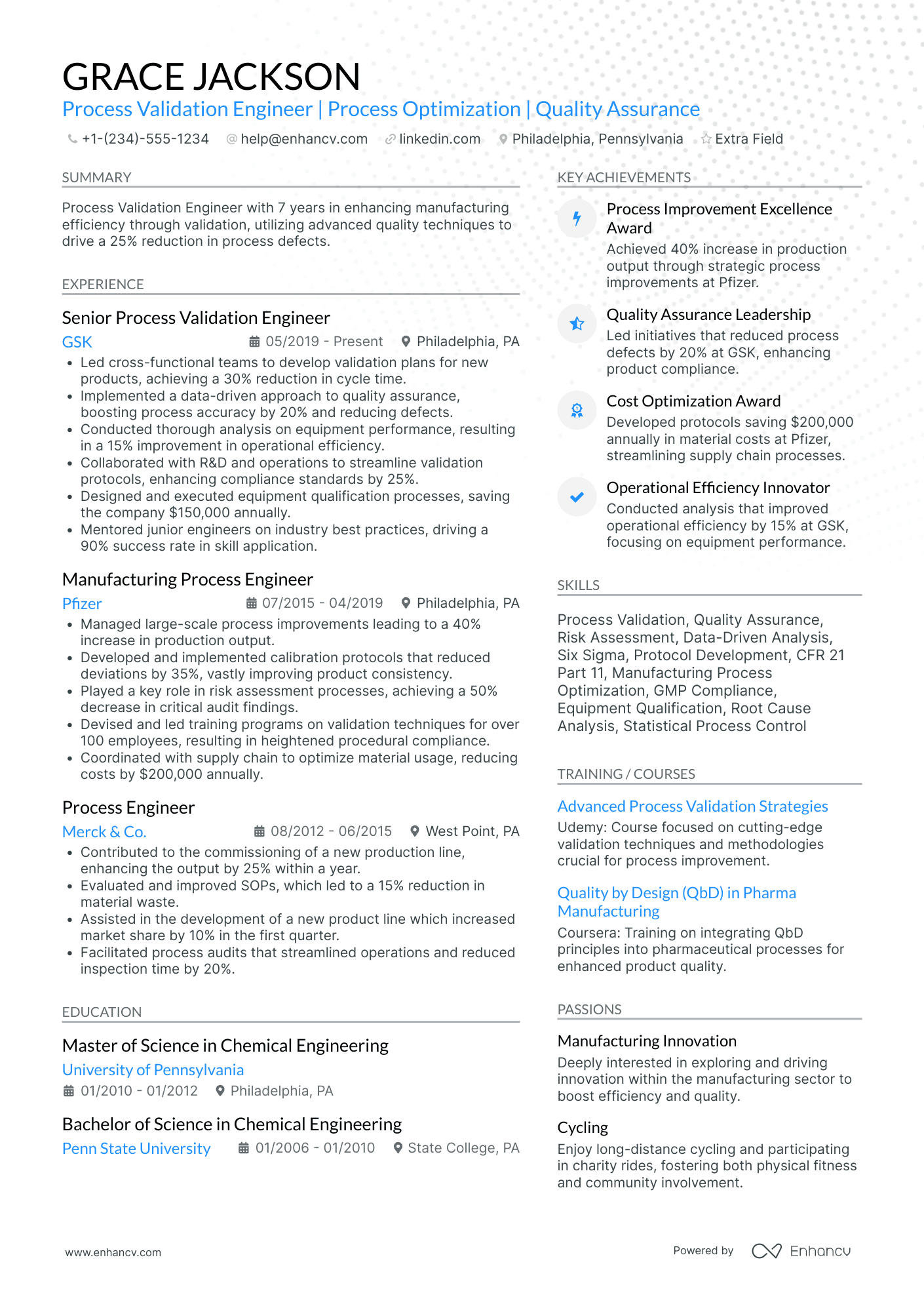

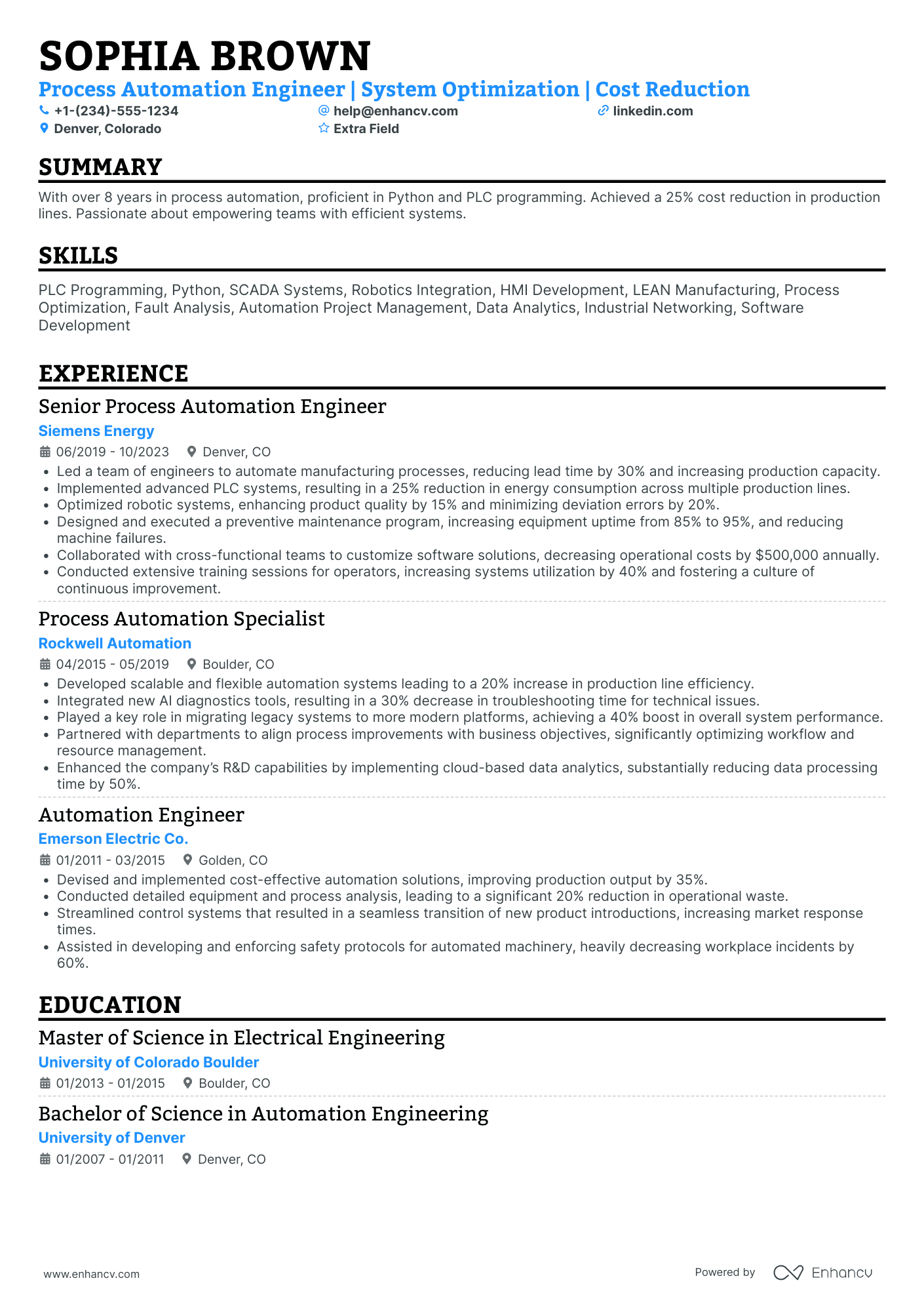

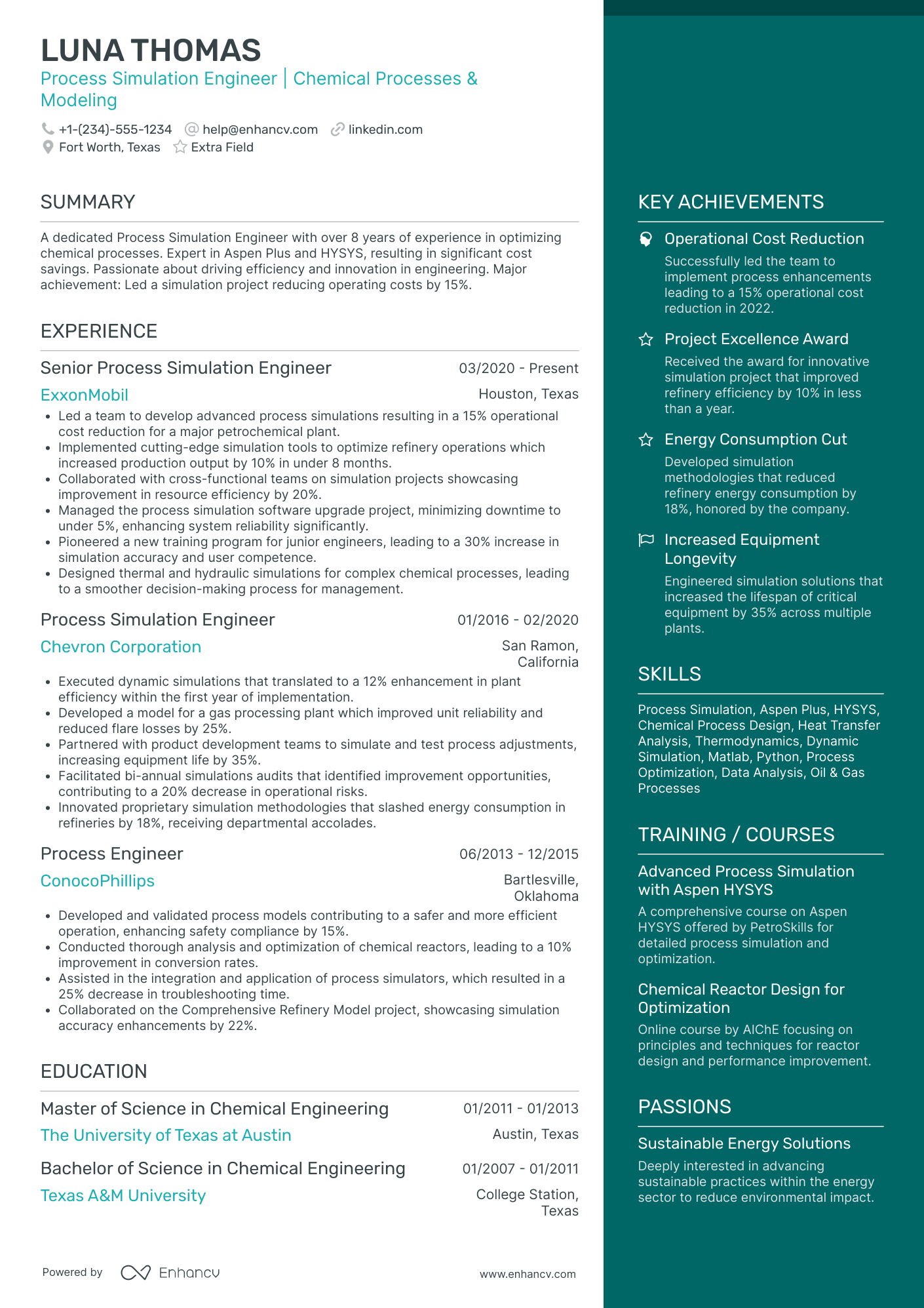

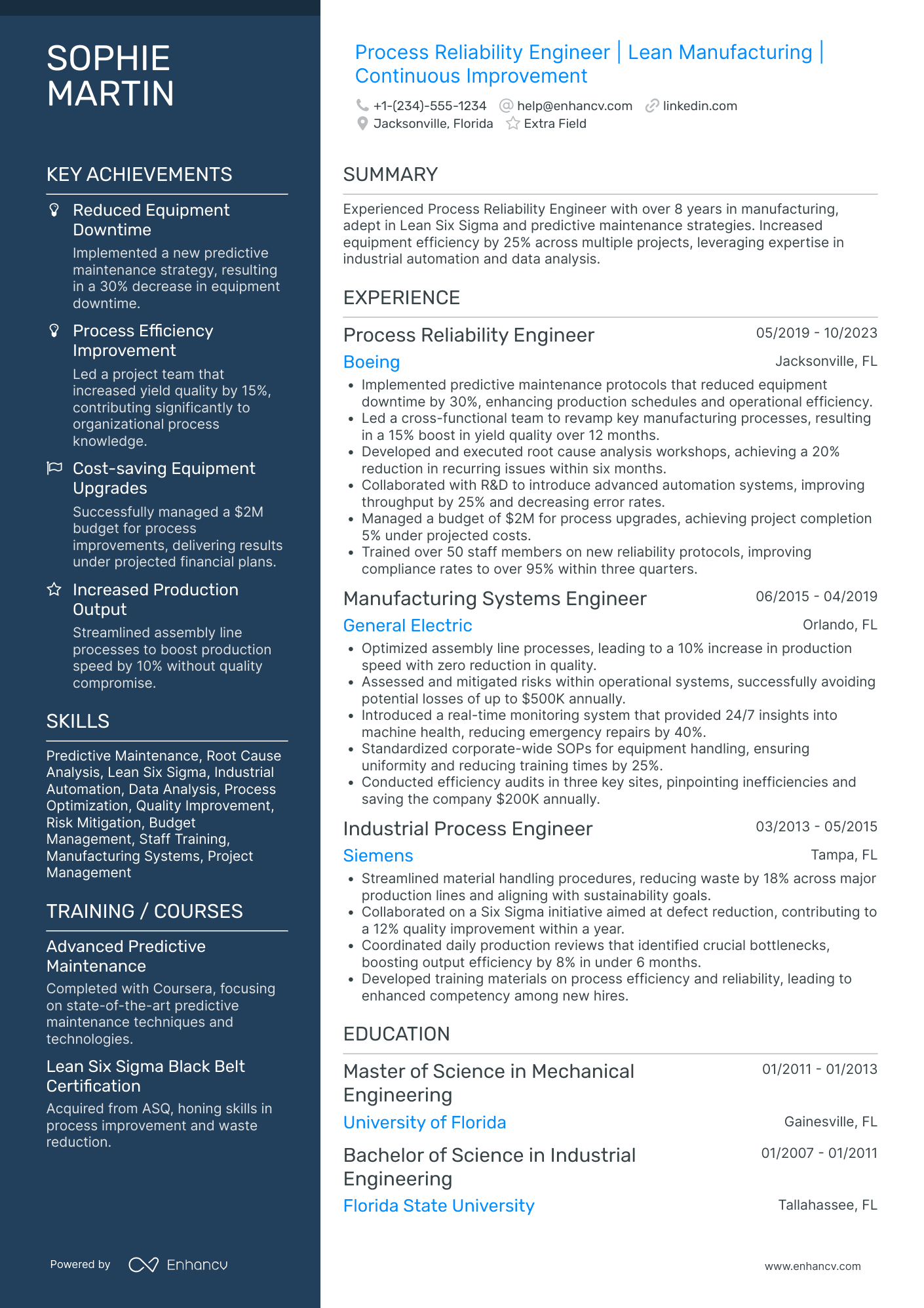

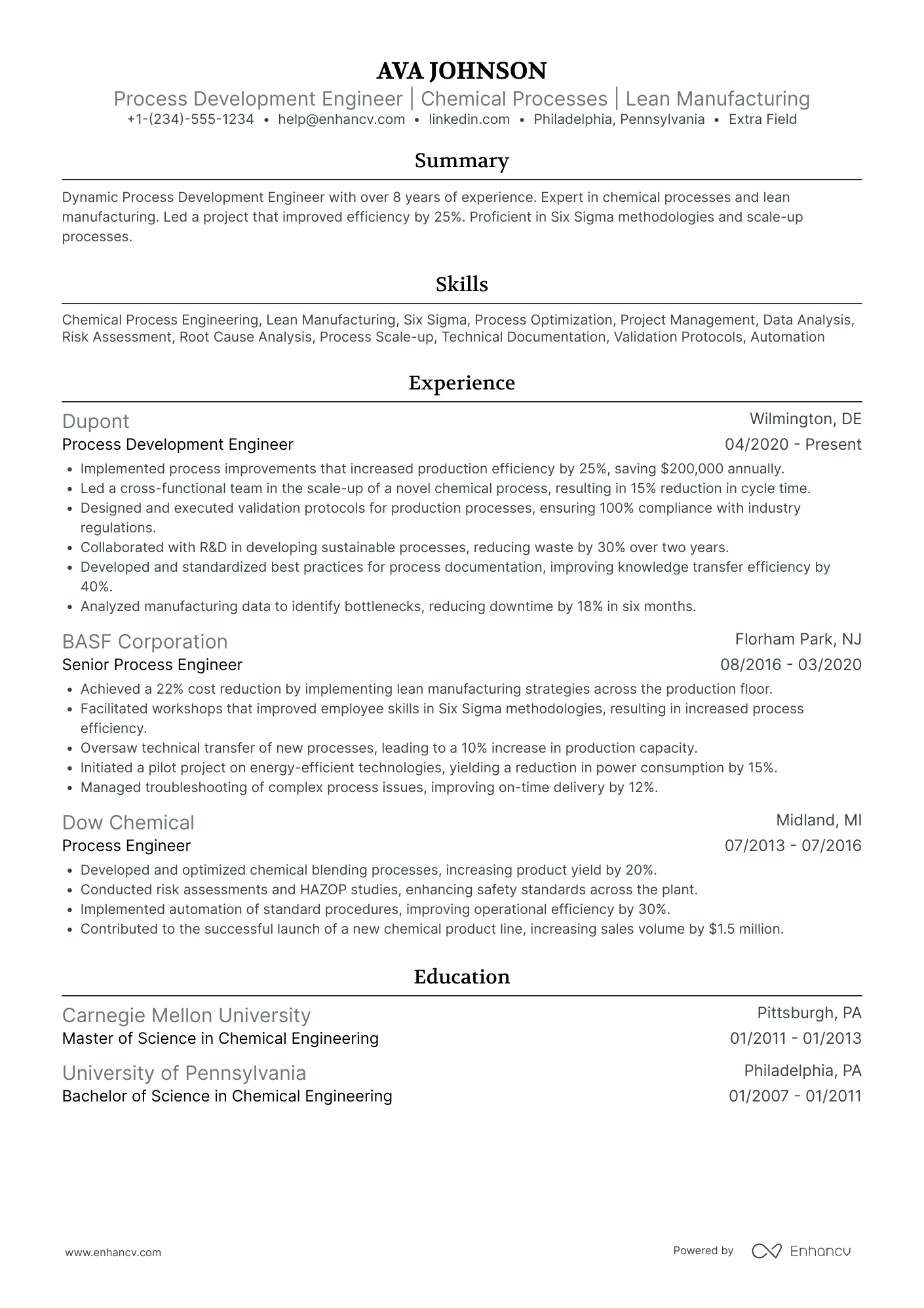

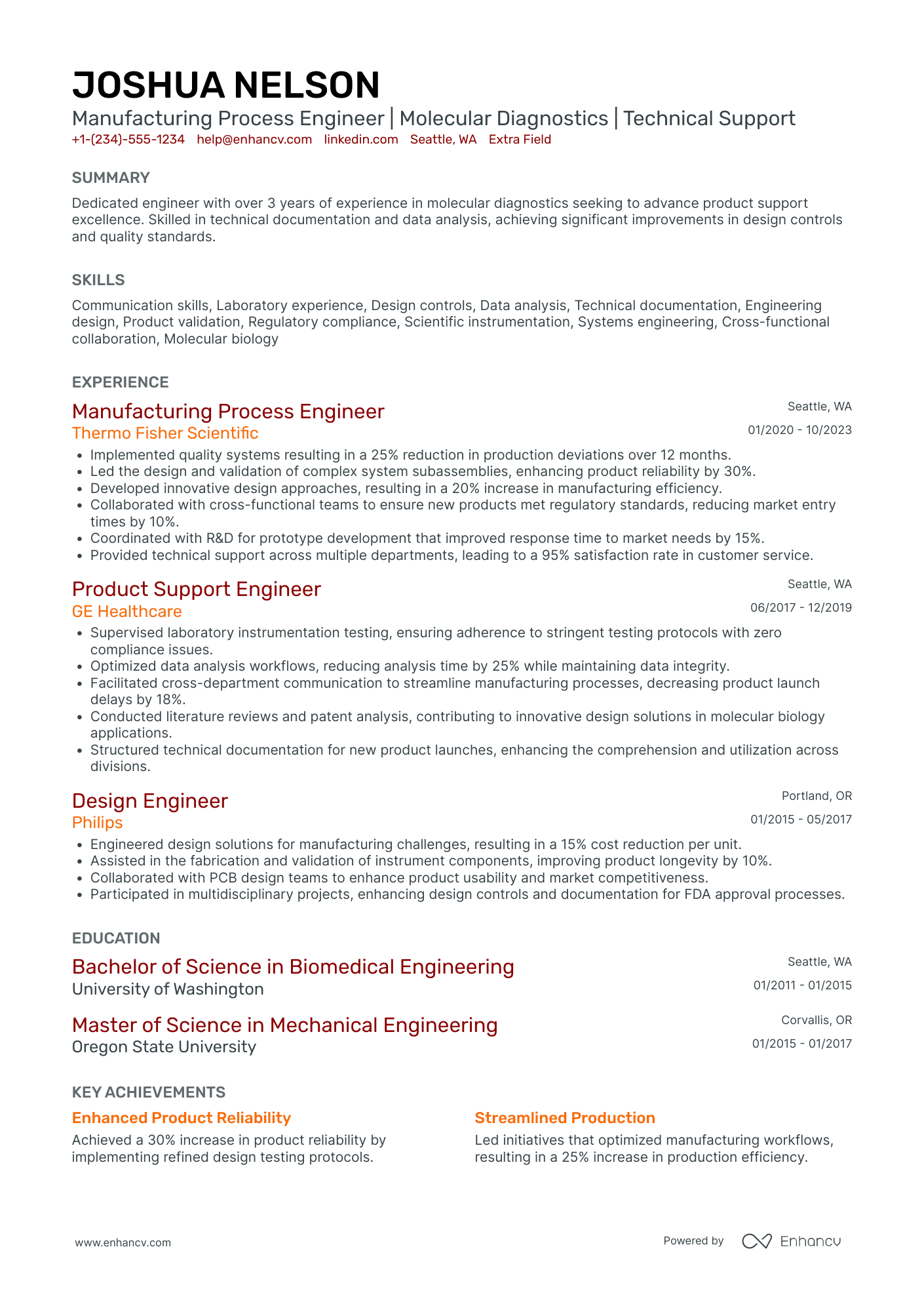

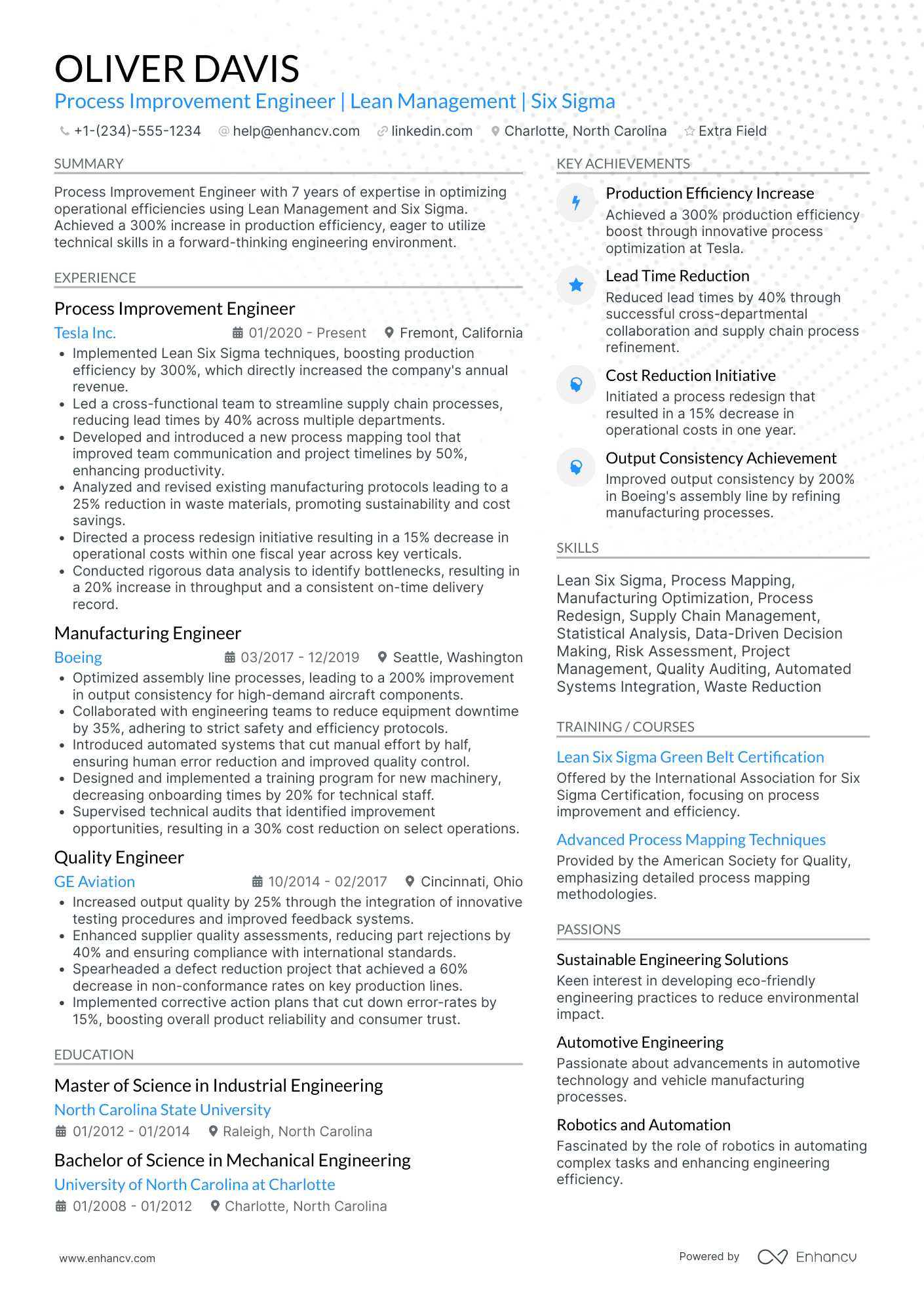

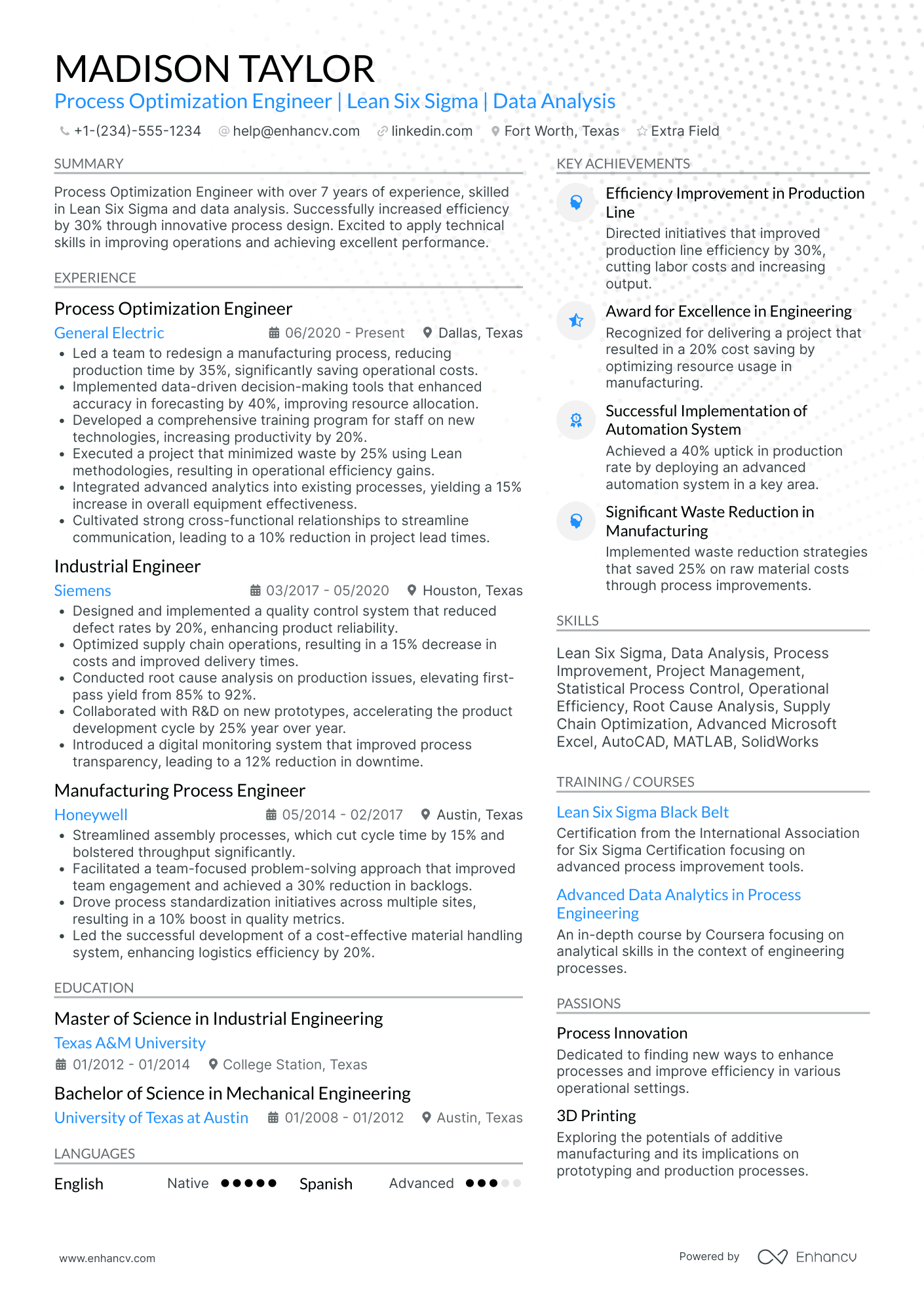

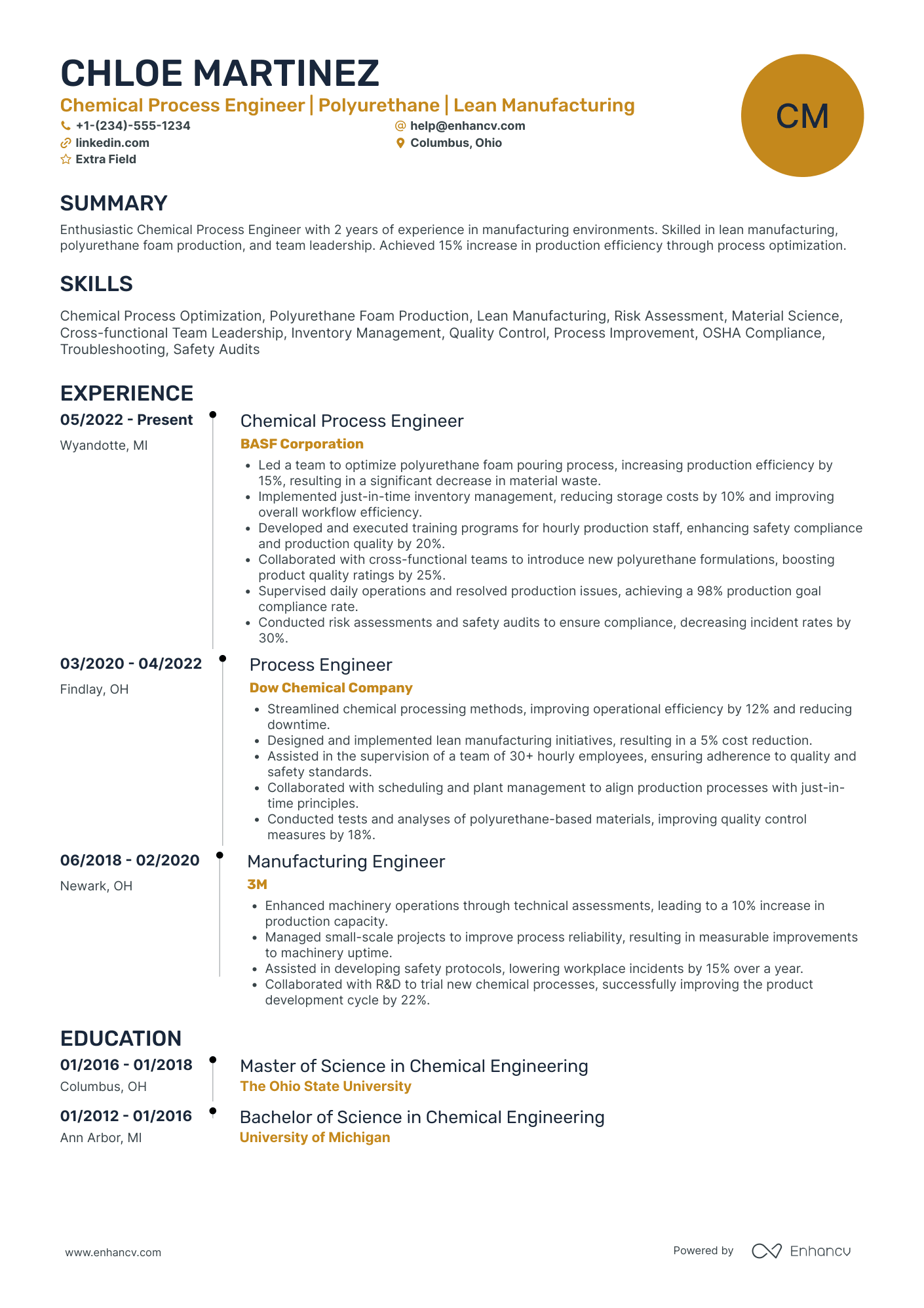

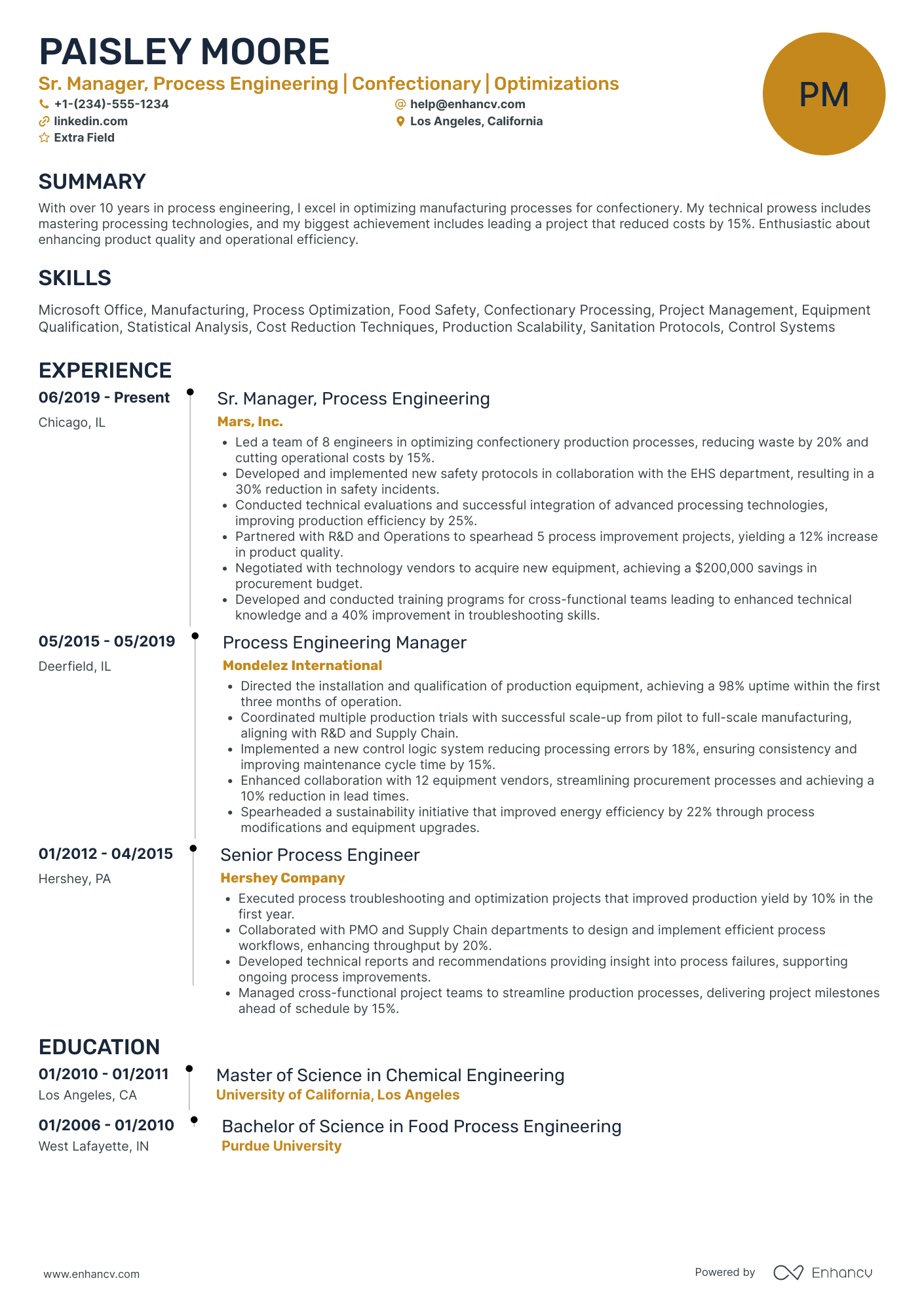

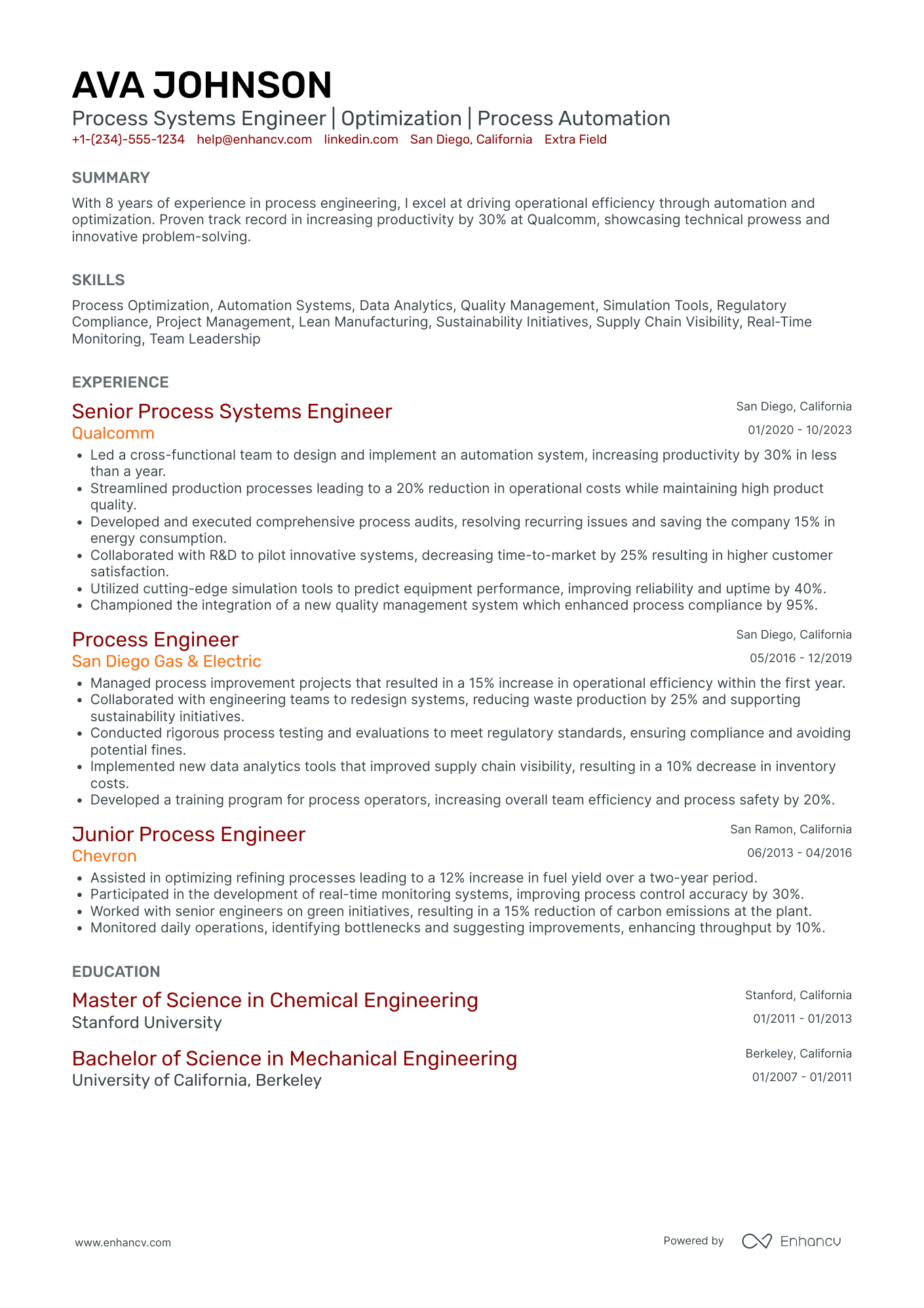

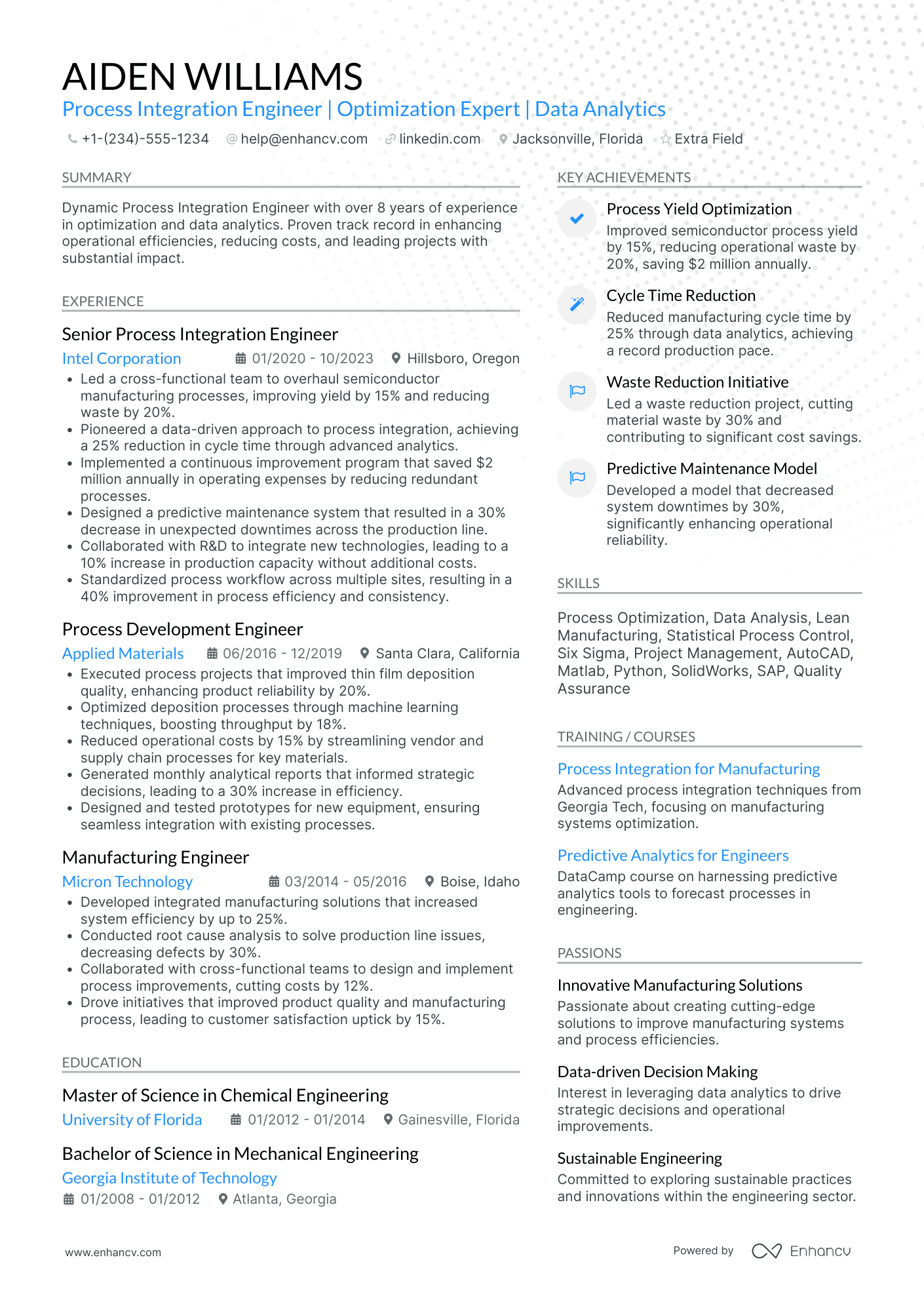

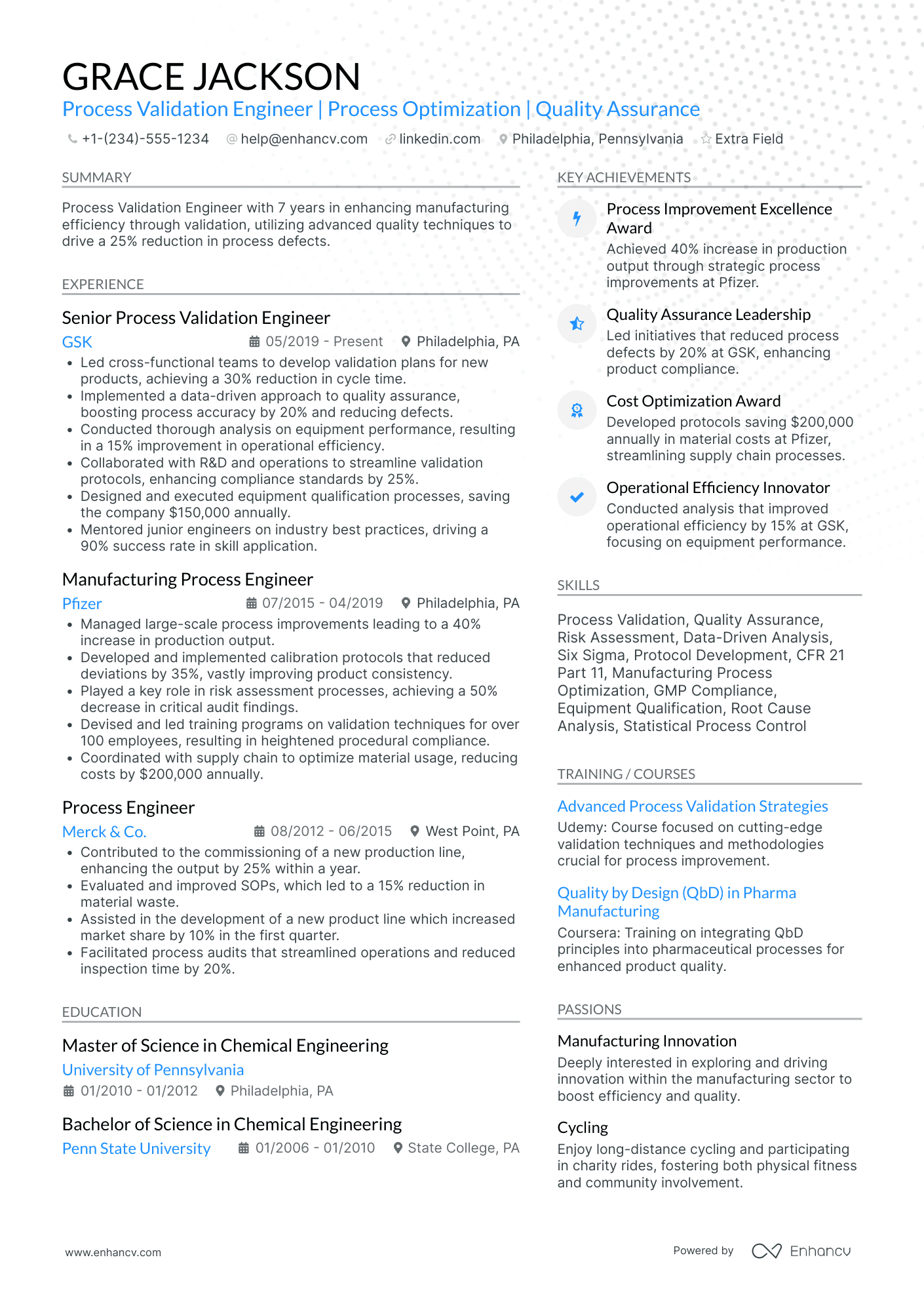

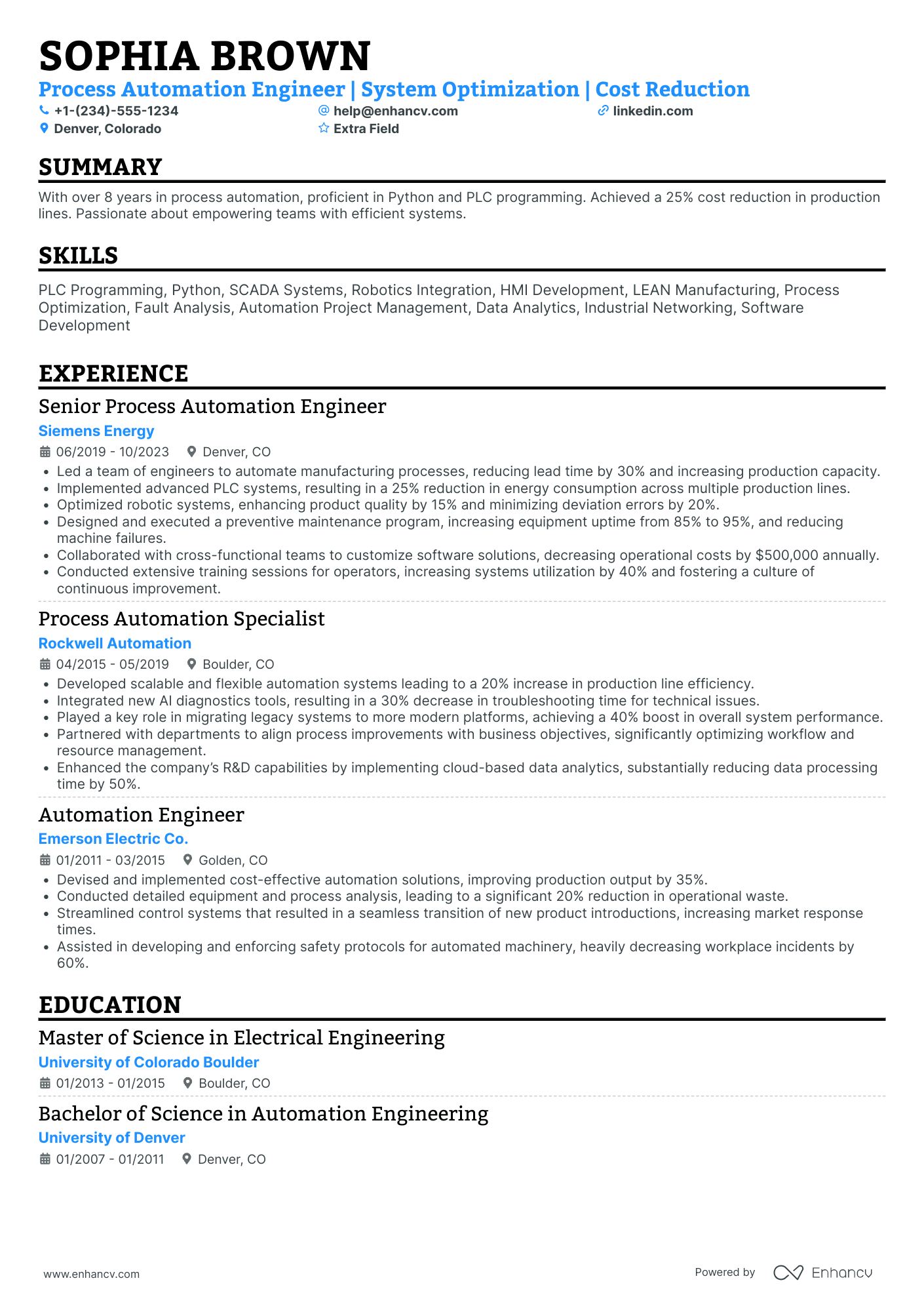

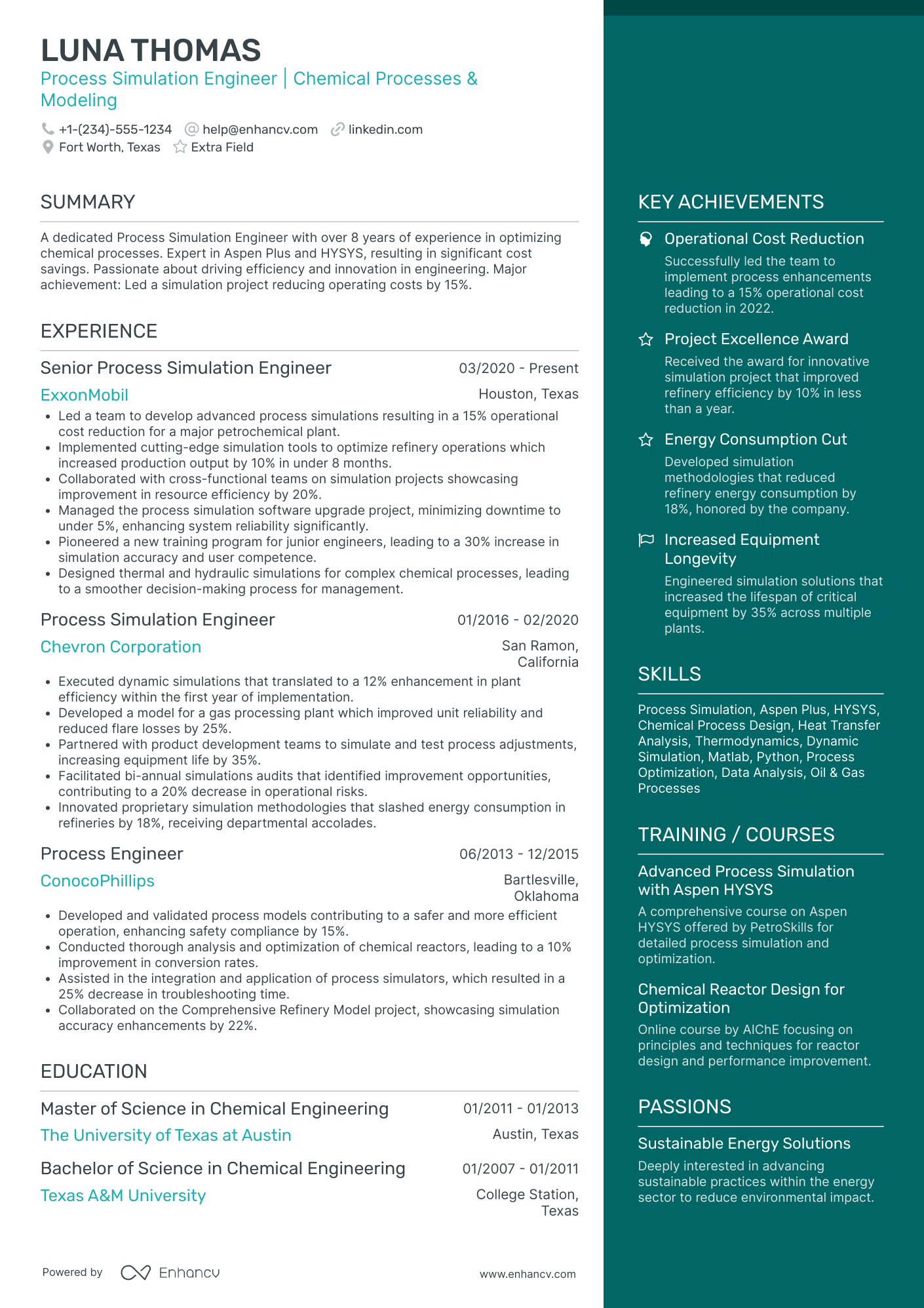

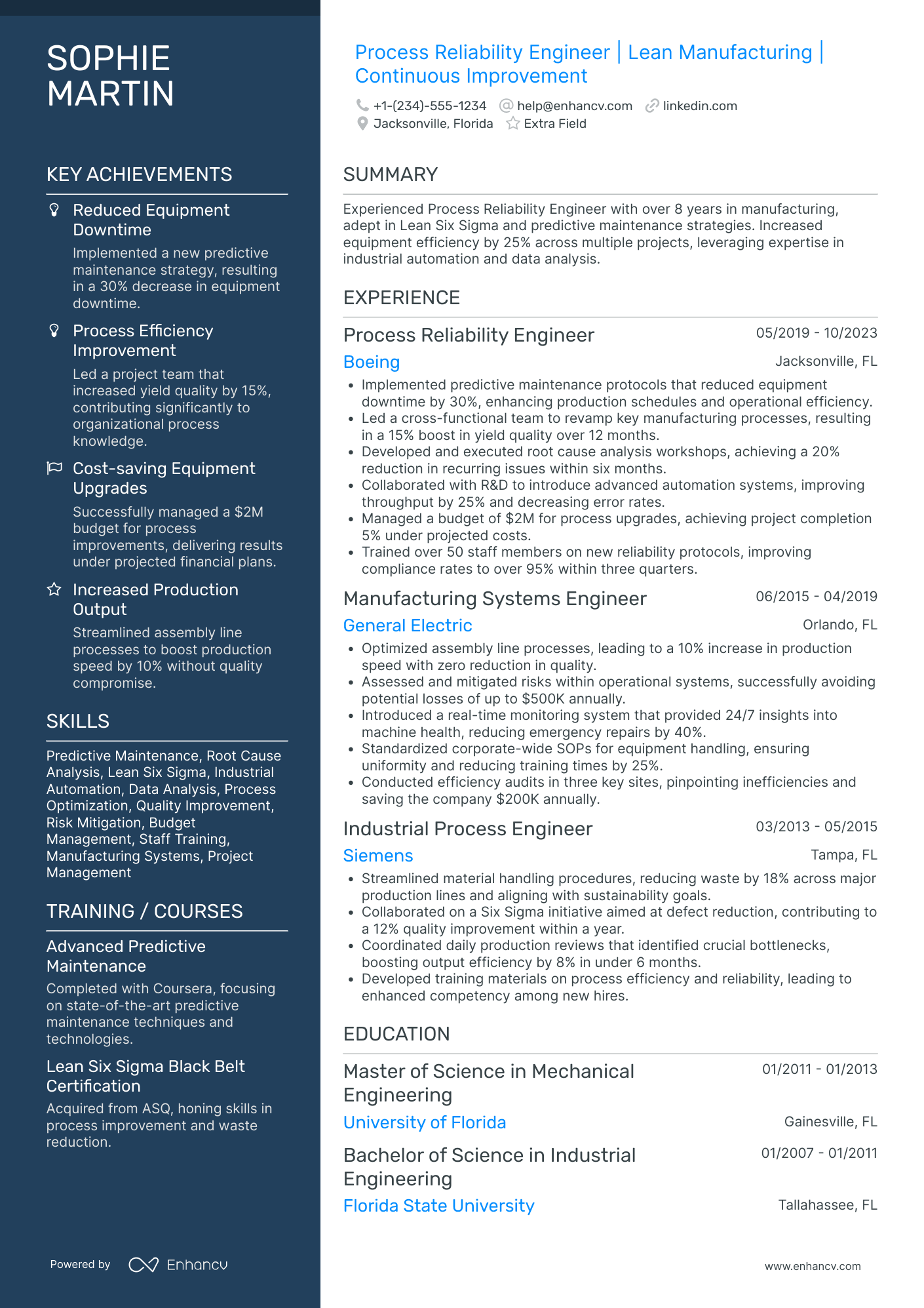

- Real-world process engineer resume samples with best practices on how to stand out amongst the endless pile of candidate resumes.

- Most in-demand process engineer resume skills and certifications across the industry.

- Standardizing your resume layout, while maintaining your creativity and individuality.

If the process engineer resume isn't the right one for you, take a look at other related guides we have:

- Marketing Product Manager Resume Example

- Clinical Project Manager Resume Example

- Principal Product Manager Resume Example

- Digital Product Manager Resume Example

- Public Health Program Manager Resume Example

- Education Program Manager Resume Example

- Mental Health Program Manager Resume Example

- Nonprofit Program Manager Resume Example

- Digital Project Manager Resume Example

- Product Development Manager Resume Example

Optimize your process engineer resume format to pass the recruiters' assessment

You may be wondering just how much time you need to spend on designing your process engineer resume.

What recruiters are looking for is systematised content that is clear and coherent. Thus, your process engineer resume needs to answer requirements and why you're the best candidate for the role from the get-go.

Often, a clear layout consists of:

- Sorting your experience in the reverse chronological order - starting with your most recent and relevant roles. This is an excellent choice for more experienced professionals;

- Writing your contact information (e.g. personal phone number and email address) and your portfolio or LinkedIn link in your process engineer resume header. If you're wondering to include a photo or not, always make sure that it's appropriate for the country you're applying in;

- Use the basic, most important process engineer resume sections - your experience, education, summary, etc. Use your resume's real estate wisely to tell a compelling, professional story and match job description's keywords;

- Don't go overboard with the length of your resume. One page is absolutely fine if you happen to have under a decade of relevant experience.

Are you still wondering if you should submit your process engineer resume in PDF or Word format ? The PDF has a few more advantages, as it doesn't change the format and the text can't be altered upon application.

Format matters most when your process engineer resume is assessed by the Applicant Tracker System (or the ATS).

The ATS parses resumes, looking for specific keywords, skills or experience that match the job description.

P.S. We recently did a study on how the ATS works and were able to demystify three of the biggest misconceptions about how it assesses candidate resumes.

To pass the ATS evaluation, select any of the serif or sans-serif fonts. Popular choices that would help your process engineer resume stand out include Raleway, Exo 2, Montserrat, etc.

Most traditionalists go for Arial or Times New Roman, but it's often the case that many candidates choose these fonts, and you'd thus lose points on the uniqueness front.

Keep in mind market-specific formats – for example, a Canadian resume might follow a different structure.

Upload & Check Your Resume

Drop your resume here or choose a file. PDF & DOCX only. Max 2MB file size.

PRO TIP

Showcase any ongoing or recent educational efforts to stay updated in your field.

The five (plus) definite sections your resume for a process engineer job should include are:

- Header with your headline, contact details, and/or a preview of your work

- Summary (or objective) to pinpoint how your success aligns with the role

- Experience with bullets of your most relevant achievements in the field

- Skills to integrate vital job requirements (both technical and personal)

- Your further dedication to the field, showcased via relevant higher education and/or certifications

What recruiters want to see on your resume:

- Demonstrated experience in process design, optimization, and scale-up

- Proficiency in process simulation and modeling tools (e.g., HYSYS, Aspen Plus)

- Understanding of P&ID development and knowledge of process control strategies

- Experience with continuous improvement methodologies (e.g., Six Sigma, Lean Manufacturing)

- Knowledge of relevant industry standards and regulations (e.g., OSHA, EPA, ISO)

Guide to your most impressive process engineer resume experience section

When it comes to your resume experience , stick to these simple, yet effective five steps:

- Show how your experience is relevant by including your responsibility, skill used, and outcome/-s;

- Use individual bullets to answer how your experience aligns with the job requirements;

- Think of a way to demonstrate the tangible results of your success with stats, numbers, and/or percentages ;

- Always tailor the experience section to the process engineer role you're applying for - this may sometimes include taking out irrelevant experience items;

- Highlight your best (and most relevant) achievements towards the top of each experience bullet.

You're not alone if you're struggling with curating your experience section. That's why we've prepared some professional, real-life process engineer resume samples to show how to best write your experience section (and more).

- Led the optimization project for the ammonia synthesis loop, enhancing conversion rates by 17% through meticulous catalyst performance evaluation.

- Implemented advanced process control strategies that reduced energy consumption by 10%, translating to annual savings of $200K for the plant operations.

- Orchestrated the successful scale-up of a new biochemical route from pilot to full-scale production, maintaining a 99% product quality consistency.

- Designed and executed experiments that led to a 25% increase in yield for a key pharmaceutical compound, significantly contributing to a boost in product margin.

- Streamlined cross-functional team efforts in the development of a new waste-water treatment process, achieving regulatory compliance 6 months ahead of schedule.

- Developed a company-wide training program on process safety management techniques, reducing safety incidents by 30% over a 2-year period.

- Coordinated with multi-disciplinary teams to troubleshoot and resolve a critical reactor bottleneck, enhancing overall plant throughput by 15%.

- Successfully managed a project to integrate a solvent recovery system into the existing production line, reclaiming 95% of solvents used and dramatically reducing environmental impact.

- Championed the application of Six Sigma methodologies to improve the efficiency of the packaging line, which decreased material waste by 40%.

- Implemented a real-time monitoring system for process parameters, which allowed for proactive adjustments and resulted in a 20% reduction in production variances.

- Led a cross-functional initiative to improve reactor cleaning procedures, decreasing downtime by 25% and extending the average run length between maintenance activities.

- Facilitated process simulation and modeling to support a $10M capital project, ensuring seamless integration with existing plant infrastructure.

- Conducted a comprehensive value stream mapping exercise for a major product line, identifying and eliminating bottlenecks that increased production capacity by 12%.

- Authored technical documentation to standardize operating procedures across the company's network of plants, fostering knowledge sharing and process consistency.

- Project-managed the installation of a new $5M distillation column, orchestrating the efforts of engineering, operations, and external contractors to deliver the project on schedule.

- Directed the adoption of lean manufacturing principles in the production process, effectively cutting lead times by 18% while maintaining product quality standards.

- Introduced and validated a novel process analytical technology (PAT) for continuous monitoring, which provided real-time data to preemptively correct deviations, improving product consistency.

- Spearheaded a capital improvement project to upgrade legacy control systems, which enhanced process reliability by 22% and reduced maintenance costs by 15%.

- Focused on sustainable process design to decrease the plant's carbon footprint; initiatives led to a 30% reduction in CO2 emissions within a 3-year span.

- Instrumental in the development of a multi-million-dollar project to retrofit and modernize a critical production facility, improving output by 20% while enhancing safety measures.

- Collaborated with R&D to pilot and commercialize a new catalyst formula, which increased process selectivity and reduced raw material costs by 10%.

- Played a key role in the facility's digital transformation by integrating IoT solutions into manufacturing systems, which led to a 15% enhancement in process visibility and control.

- Managed the selection and implementation of a new manufacturing execution system (MES), which improved operational efficiency and data accuracy.

- Authored a white paper on predictive maintenance for critical equipment, which was adopted company-wide and resulted in a 20% decrease in unscheduled downtime.

The following content includes information from "O*NET OnLine" by the U.S. Department of Labor, Employment and Training Administration (USDOL/ETA). Used under the CC BY 4.0 license. The data represents the top responsibilities present on the task lists for process engineer professionals.

Top Responsibilities for Process Engineer:

- Evaluate the safety, efficiency, and effectiveness of biomedical equipment.

- Prepare technical reports, data summary documents, or research articles for scientific publication, regulatory submissions, or patent applications.

- Design or develop medical diagnostic or clinical instrumentation, equipment, or procedures, using the principles of engineering and biobehavioral sciences.

- Conduct research, along with life scientists, chemists, and medical scientists, on the engineering aspects of the biological systems of humans and animals.

- Adapt or design computer hardware or software for medical science uses.

- Maintain databases of experiment characteristics or results.

- Develop statistical models or simulations, using statistical or modeling software.

- Read current scientific or trade literature to stay abreast of scientific, industrial, or technological advances.

- Manage teams of engineers by creating schedules, tracking inventory, creating or using budgets, or overseeing contract obligations or deadlines.

- Develop models or computer simulations of human biobehavioral systems to obtain data for measuring or controlling life processes.

Quantifying impact on your resume

- Include the percentage reduction in process downtime achieved through optimization initiatives to demonstrate efficiency improvements.

- List the dollar value of cost savings realized from materials or energy consumption reductions to highlight financial impact.

- Document the increase in production capacity or throughput due to process redesigns to show scalability contributions.

- State the number of projects led or co-led, reflecting leadership experience and project management skills.

- Quantify the improvement in product quality or decrease in defect rates to exhibit commitment to excellence.

- Mention the amount of time reduced in the production cycle by implementing new technologies or methodologies.

- Present the size of the teams you've worked with to underscore collaboration and interpersonal abilities.

- Specify the number of patents or publications, if any, to validate innovation and domain expertise.

Action verbs for your process engineer resume

Writing your process engineer experience section without any real-world experience

Professionals, lacking experience, here's how to kick-start your process engineer career:

- Substitute experience with relevant knowledge and skills, vital for the process engineer role

- Highlight any relevant certifications and education - to showcase that you have the relevant technical training for the job

- Definitely include a professional portfolio of your work so far that could include university projects or ones you've done in your free time

- Have a big focus on your transferable skills to answer what further value you'd bring about as a candidate for the process engineer job

- Include an objective to highlight how you see your professional growth, as part of the company

Recommended reads:

PRO TIP

If you happen to have some basic certificates, don't invest too much of your process engineer resume real estate in them. Instead, list them within the skills section or as part of your relevant experience. This way you'd ensure you meet all job requirements while dedicating your certificates to only the most in-demand certification across the industry.

Bringing your process engineer hard skills and soft skills to the forefront of recruiters' attention

Hard skills are used to define the technological (and software) capacities you have in the industry. Technical skills are easily defined via your certification and expertise.

Soft skills have more to do with your at-work personality and how you prosper within new environments. People skills can be obtained thanks to your whole life experience and are thus a bit more difficult to define.

Why do recruiters care about both types of skills?

Hard skills have more to do with job alignment and the time your new potential employers would have to invest in training you.

Soft skills hint at how well you'd adapt to your new environment, company culture, and task organization.

Fine-tune your resume to reflect on your skills capacities and talents:

- Avoid listing basic requirements (e.g. "Excel"), instead substitute with the specifics of the technology (e.g. "Excel Macros").

- Feature your workplace values and ethics as soft skills to hint at what matters most to you in a new environment.

- Build a separate skills section for your language capabilities, only if it makes sense to the role you're applying for.

- The best way to balance process engineer hard and soft skills is by building a strengths or achievements section, where you define your outcomes via both types of skills.

There are plenty of skills that could make the cut on your resume.

That's why we've compiled for you some of the most wanted skills by recruiters, so make sure to include the technologies and soft skills that make the most sense to you (and the company you're applying for):

Top skills for your process engineer resume:

Process Simulation Software (e.g., Aspen Plus, HYSYS)

Data Analysis Tools (e.g., MATLAB, Python)

Statistical Process Control (SPC)

Lean Manufacturing Techniques

Six Sigma Methodologies

Computer-Aided Design (CAD) Software

Process Control Systems (e.g., PLC, DCS)

Quality Management Systems (QMS)

Project Management Software (e.g., MS Project, Trello)

Process Mapping and Flowcharting Tools

Problem-Solving

Communication

Team Collaboration

Critical Thinking

Time Management

Adaptability

Attention to Detail

Creativity

Leadership

Conflict Resolution

Next, you will find information on the top technologies for process engineer professonals from "O*NET OnLine" by the U.S. Department of Labor, Employment and Training Administration (USDOL/ETA). Used under the CC BY 4.0 license.

Top technologies for Process Engineer’s resume:

- SAS

- The MathWorks MATLAB

- Extensible markup language XML

- Microsoft Teams

- Autodesk AutoCAD

- Dassault Systemes SolidWorks

PRO TIP

Mention specific courses or projects that are pertinent to the job you're applying for.

Discover the perfect certification and education to list on your process engineer resume

Value the insights your resume education section offers. It can shed light on various proficiencies and experiences tailored for the job.

- Add only college or university degrees, stating the institution and duration.

- If you're nearing the end of your degree, note your graduation date.

- Weigh the pros and cons of including unrelated degrees - it might not be your best choice with so little space on your resume.

- Talk about your educational achievements if they amplify your relevant experience.

There are so many certificates you can list on your resume.

Just which ones should make the cut?

- List your prominent higher education degree in a separate box, alongside the name of the institute you've obtained it from and your graduation dates

- Curate only relevant certificates that support your expertise, hard skills, and soft skills

- Certificates that are more niche (and rare) within the industry could be listed closer to the top. Also, this space could be dedicated to more recent certifications you've attained

- Add a description to your certificates or education, only if you deem this could further enhance your chances of showcasing your unique skill set

When listing your certificates, remember that it isn't a case of "the more, the merrier", but rather "the more applicable they are to the industry, the better".

Recruiters have hinted that these are some of the most in-demand certificates for process engineer roles across the industry:

The top 5 certifications for your process engineer resume:

- Certified Six Sigma Green Belt (CSSGB) - American Society for Quality (ASQ)

- Project Management Professional (PMP) – Project Management Institute (PMI)

- Professional Engineer (PE) – National Society of Professional Engineers (NSPE)

- Certified Energy Manager (CEM) – Association of Energy Engineers (AEE)

- Lean Certification – Society of Manufacturing Engineers (SME)

The content below includes information from "O*NET OnLine" by the U.S. Department of Labor, Employment and Training Administration (USDOL/ETA). Used under the CC BY 4.0 license. The data represents the top associations for process engineer professionals.

Top US associations for a Process Engineer professional

- IEEE Engineering in Medicine and Biology Society

- Accreditation Board for Engineering and Technology

- American Association for the Advancement of Science

- American Board for Certification in Orthotics, Prosthetics and Pedorthics

- American Chemical Society

PRO TIP

The more trusted the organization you've attained your certificate (or degree) from, the more credible your skill set would be.

Recommended reads:

Process engineer resume summaries or objectives: real-world samples for best industry practices

Grasp recruiters' attention from the get-go of your application with a professional process engineer resume summary or objective.

It's wise to select the:

- Resume objective , if you don't happen to have much experience alignment and would like to more prominently feature your dreams and personality.

- Resume summary , if you'd like to have a more standard approach to your application and feature up to five career highlights to help you stand out.

Writing your resume summary or objective should be tailored to each role you apply for.

Think about what would impress the recruiters and go from there.

But, if you need further help with this introductory section, check out some real-world samples in the next part of this guide:

Resume summaries for a process engineer job

- With over eight years of expertise optimizing petrochemical processes at ExxonMobil, my hands-on experience in streamlining operations through effective use of Six Sigma methodologies has significantly uplifted production efficiency by 23%. I seek to leverage my in-depth understanding of process simulations and advanced statistical analysis to drive performance improvements in a challenging environment.

- Adept in software development with a 5-year tenure at Google, I am equipped with a robust analytical mindset and coding expertise. My quest is now to pivot towards process engineering, utilizing my systematic approach to solving complex problems and my proficiency in Python and data structures to contribute to process optimization and workflow enhancements.

- Transitioning from a decade of experience in elite road construction management, I bring a rich knowledge of project execution, safety protocols, and logistic optimization. My ambition is to transfer this background into process engineering, ensuring effective system integration and operational excellence through relentless pursuit of continuous improvement methods.

- Enthusiastic about launching a career in process engineering, I am armed with a fresh Master's degree in Chemical Engineering from MIT and internships at DuPont which enhanced my proficiency in process design and risk management. Motivated by an objective to develop innovative solutions to drive industrial processes, ready to embrace rigorous training and collaborative work.

- Recently graduated with high honors in industrial engineering from Stanford University, I am eager to apply my understanding of production systems and supply chain management in a process engineering role. I aim to combine state-of-the-art research, practical intern experience, and my passion for sustainable manufacturing practices to improve existing processes and develop new operational strategies.

Optimize your resume summary and objective for ATS

Drop your resume here or choose a file.

PDF & DOCX only. Max 2MB file size.

Average salary info by state in the US for process engineer professionals

Local salary info for Process Engineer.” Source: My Next Move, National Center for O*NET Development. Accessed 10/15/2024

| State | Average Salary (in USD) |

|---|---|

| US National Average | $100,730 |

| California (CA) | $108,950 |

| Texas (TX) | $85,780 |

| Florida (FL) | $98,960 |

| New York (NY) | $109,340 |

| Pennsylvania (PA) | $94,840 |

| Illinois (IL) | $93,120 |

| Ohio (OH) | $100,000 |

| Georgia (GA) | $102,640 |

| North Carolina (NC) | $100,490 |

| Michigan (MI) | $101,980 |

Recruiters' favorite additional process engineer resume sections

When writing your process engineer resume, you may be thinking to yourself, " Is there anything more I can add on to stand out? ".

Include any of the below four sections you deem relevant, to ensure your process engineer resume further builds up your professional and personal profile:

Key takeaways

- All aspects of your resume should be selected to support your bid for being the perfect candidate for the role;

- Be intentional about listing your skill set to be balanced with both technical and people capabilities, while aligning with the job;

- Include any experience items that are relevant to the role and ensure you feature the outcomes of your responsibilities;

- Use the summary or objective as a screenshot of your best experience highlights;

- Curate various resume sections to showcase personal, transferable skills.

Process Engineer resume examples

By Experience

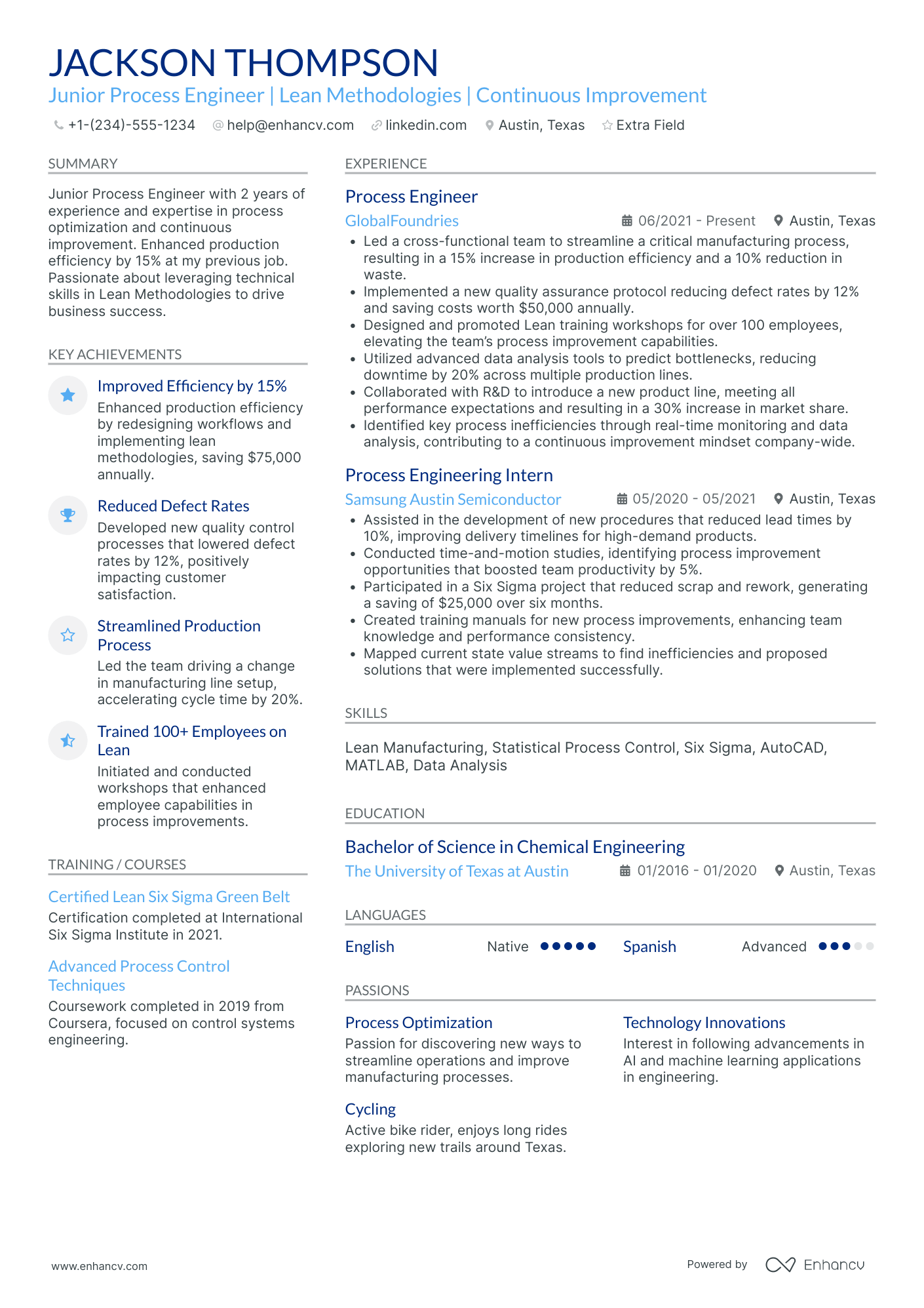

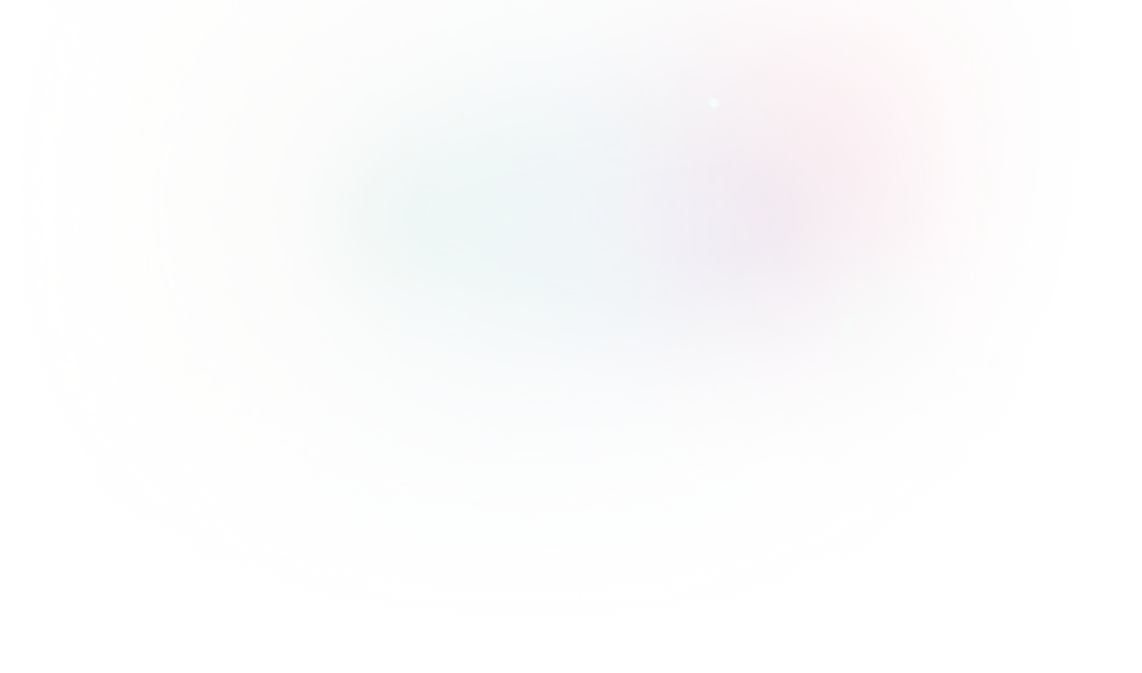

Junior Process Engineer

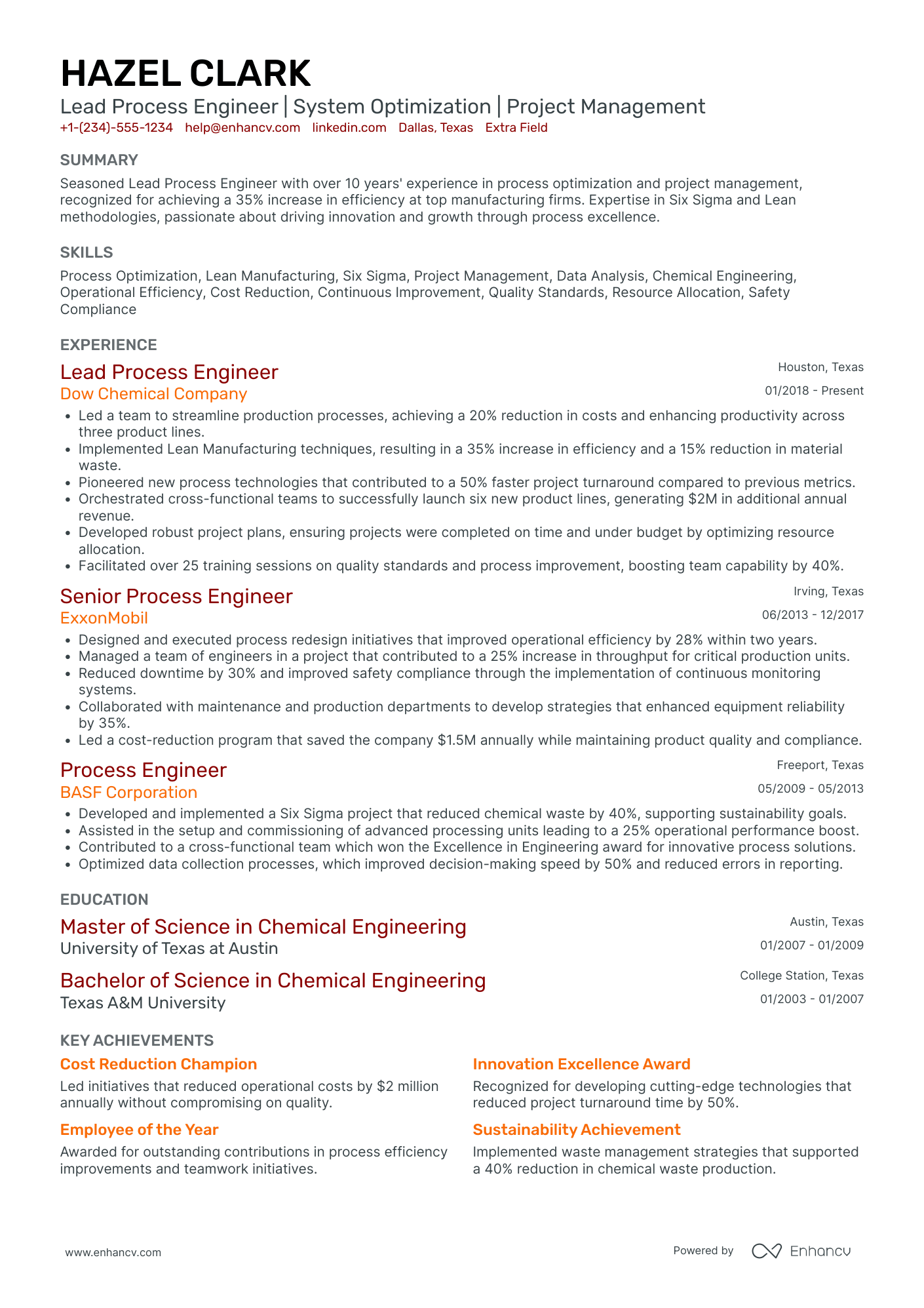

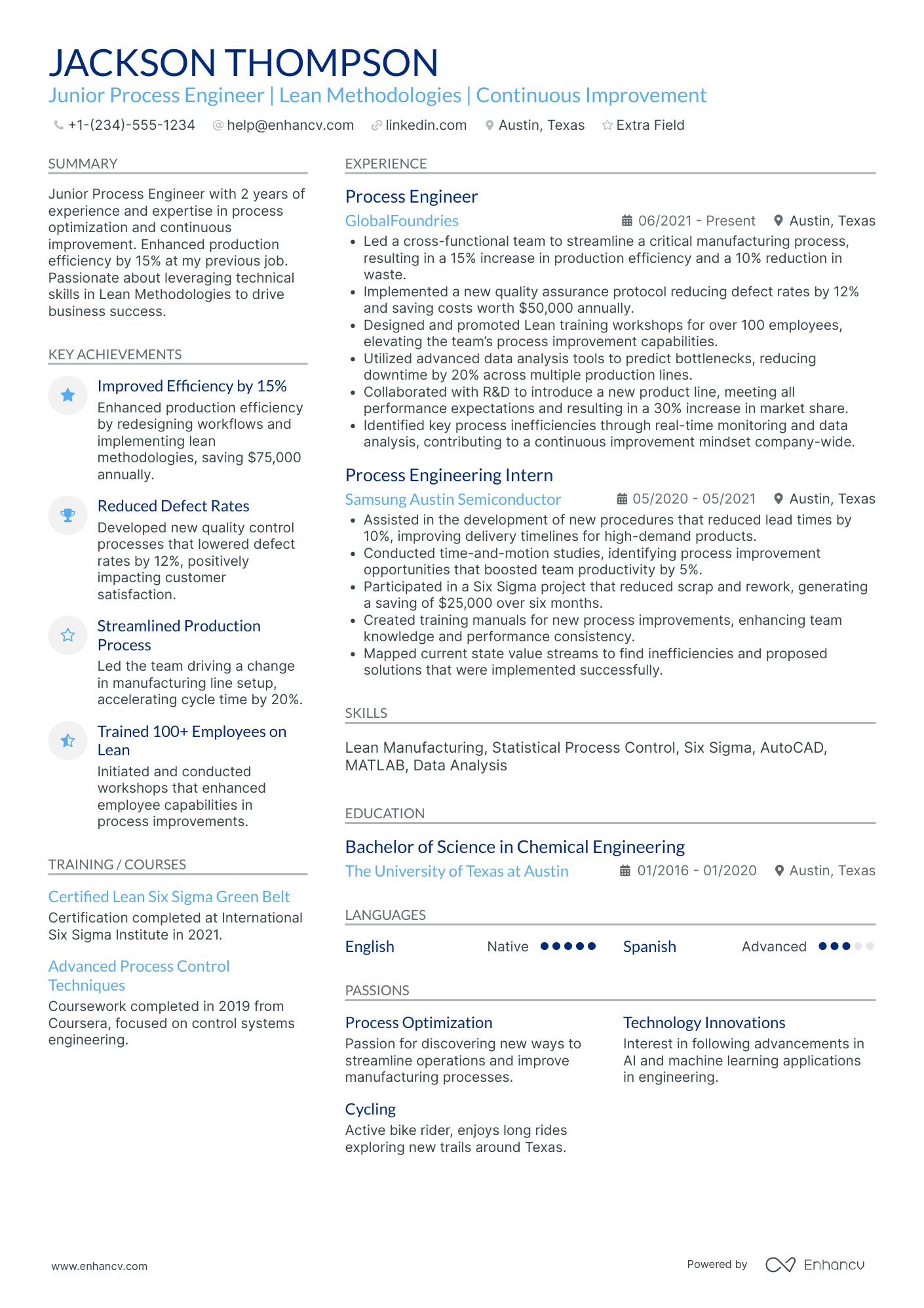

Lead Process Engineer

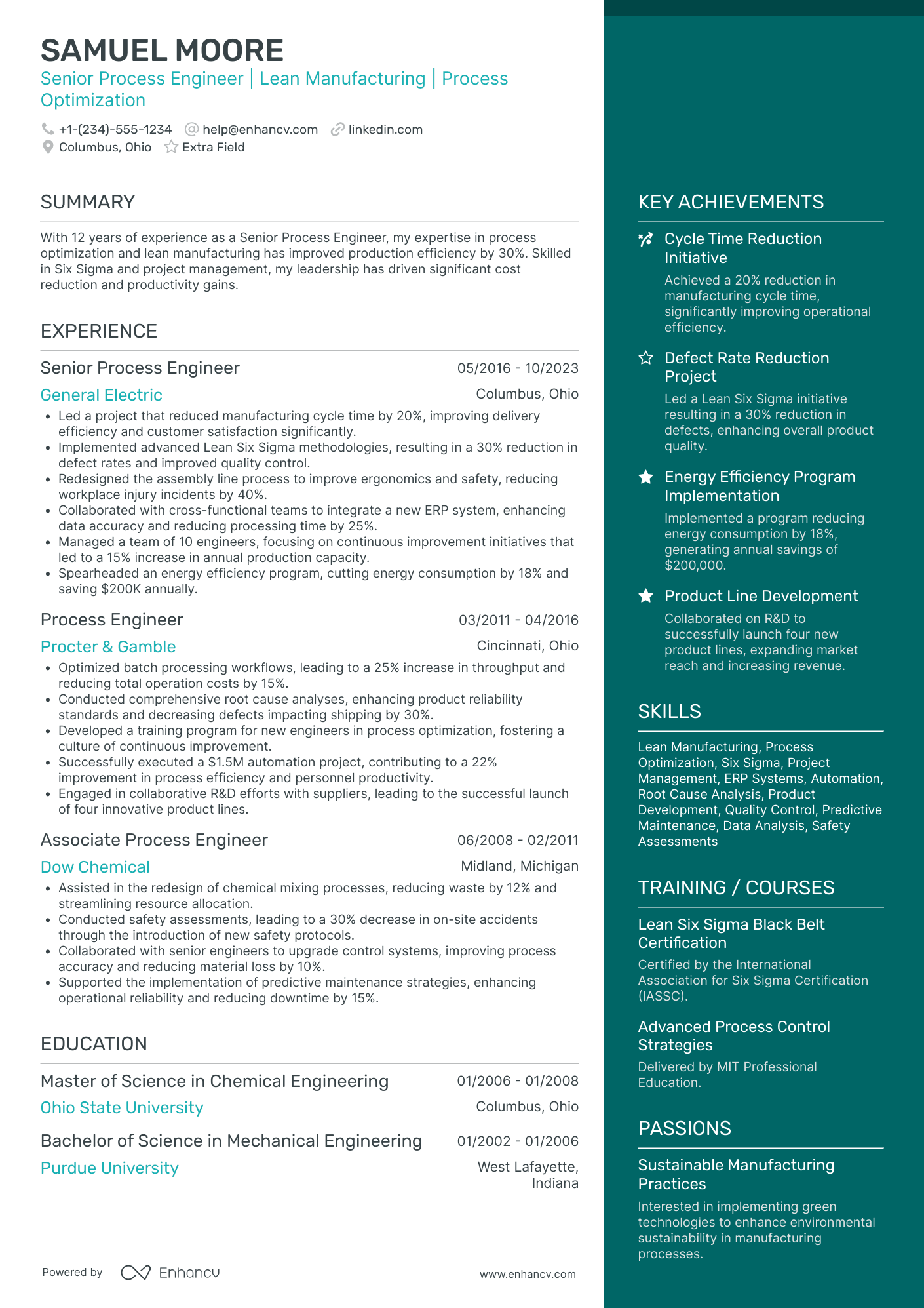

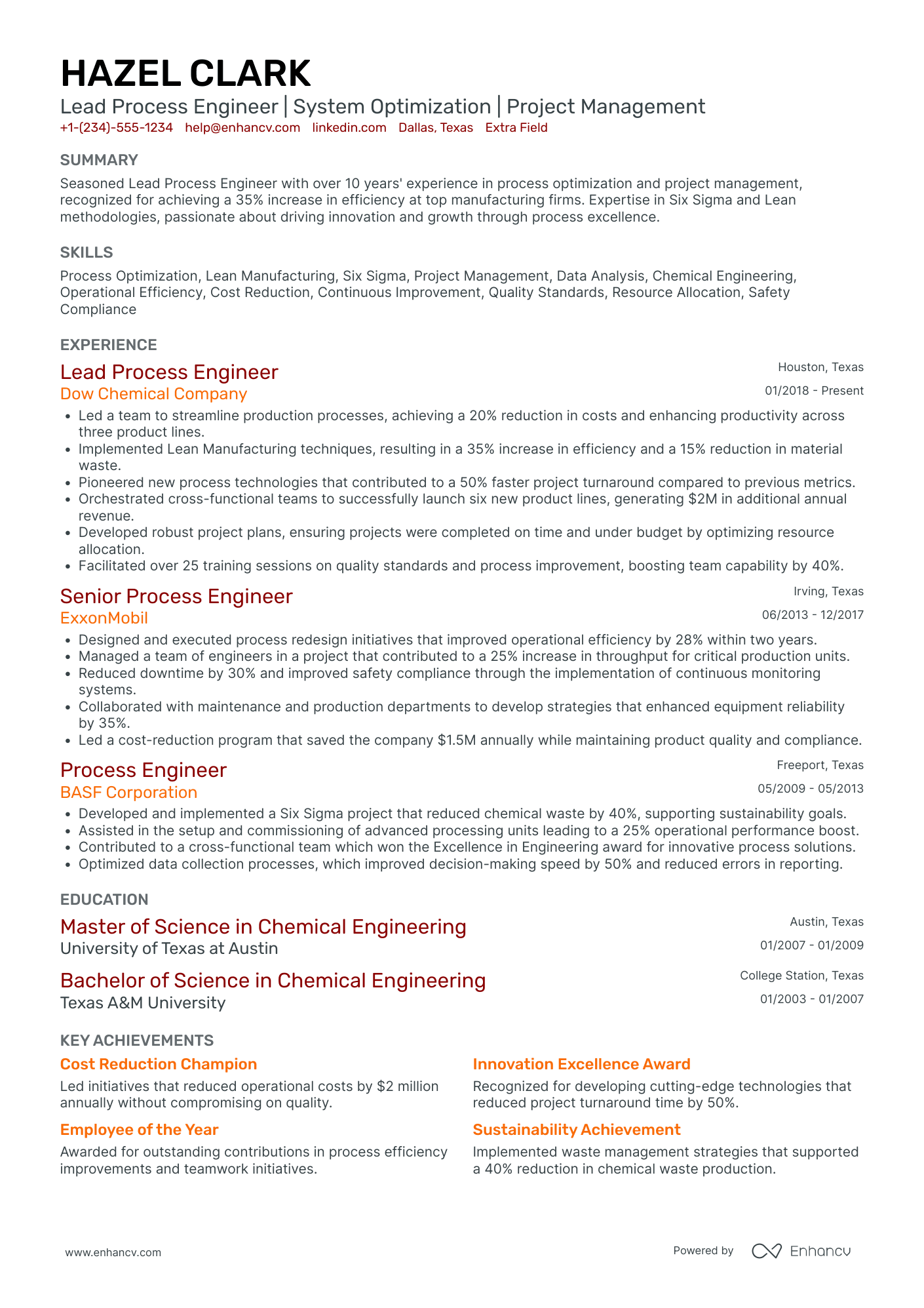

Senior Process Engineer

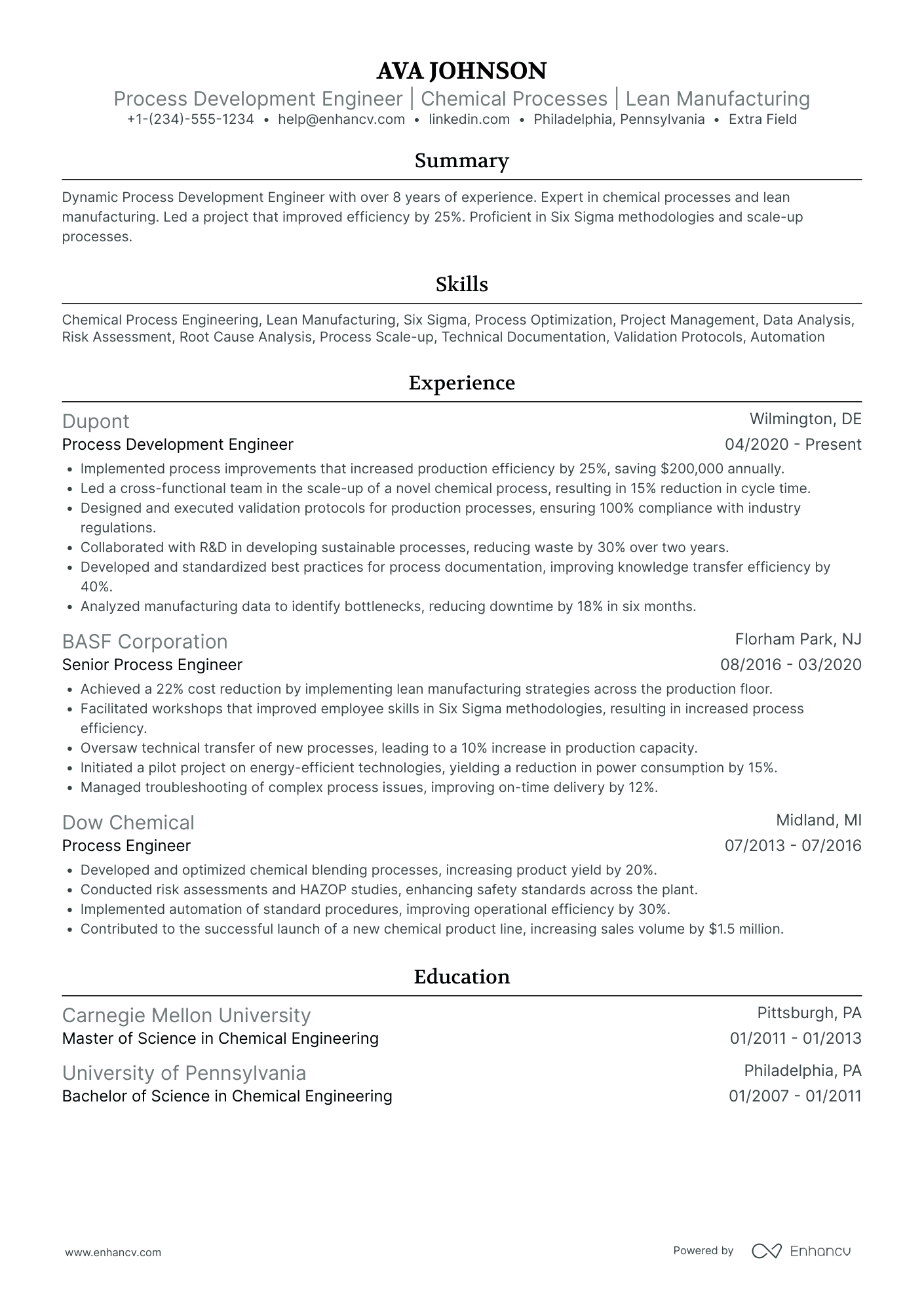

By Role